Multifunctional Vertical Rotating Conveyor

Pillar Rotary Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

The pillar rotary tower is a supporting equipment for automated production of moon-cakes, hamburgers, cakes, etc. in small spaces. It is designed with a composite plastic steel conveyor belt and other materials to achieve high-speed, fixed upward or downward transportation in minimal space. The equipment is characterized by its sleek and sturdy appearance, stable transmission, easy operation, and low maintenance costs. It is a widely used conveying device in the field of material handling today, and the number of layers, layer height, tower diameter, and tower height can be customized according to the customer's production capacity requirements. As a leading China vertical rotating conveyor manufacturer, we ensure that each conveyor meets rigorous standards for durability and performance.

Multifunctional Vertical Rotating Conveyor Specifications

| Product Name | Pillar Rotary Tower |

| Model | KC-ZSX-01 |

| Voltage | 380V3N |

| Power | 1.5kW |

| Width | 1000-3000 |

| Height | 1000-10000 |

| Conveyor Material | POM |

Multifunctional Vertical Rotating Conveyor Advantage

As a trusted provider in this industry, our expertise as a vertical rotating conveyor manufacturer enables us to deliver top-quality, efficient conveyors that meet the dynamic requirements of modern material handling.

1.The conveyor belt of the pillar rotary tower is made of high-strength food-grade plastic, as well as logistics transport plastic, which has the advantages of wear-resistance, corrosion-resistance, easy cleaning, non-stickiness to products, and non-destructiveness to product surfaces.

2. With the function of multi-purpose use, it occupies a small space. The upward or downward transportation of products is stable and fast, greatly saving transportation time.

3. Integrated with manual and automatic operations, it is easy to control, has low noise, high stability, and a low failure rate.

4. It features fully automatic intelligent control and a simple and intuitive touch screen operation interface, making it efficient and energy saving, suitable for batch and continuous production.

Multifunctional Vertical Rotating Conveyor FAQ

Q: What are the main features of the multi-column spiral tower?

A: The multi-column spiral tower features an aesthetically pleasing and sturdy design, with smooth conveyance and low maintenance costs. Additionally, we can customize the size according to customer requirements, making it ideal for batch and continuous production.

Q: What industries or applications is this spiral tower suitable for?

A: The multi-column spiral tower is widely used in the food industries, particularly suitable for scenarios requiring vertical or inclined material conveyance.

Q: What is the process for customizing the size?

A: Customers only need to provide specific size requirements and conveyance needs, and our engineers will design a spiral tower that meets your requirements while ensuring stability and efficiency.

Q: Why is the maintenance cost of the spiral tower low?

A: Our spiral tower features a simple design with easily removable and replaceable parts, and uses wear-resistant and corrosion-resistant materials, reducing the cost of daily maintenance and repairs.

Q: How do you ensure the smooth conveyance of the spiral tower?

A: The multi-column spiral tower adopts advanced transmission systems and structural designs to ensure smooth and bump-free conveyance of materials, protecting them from damage during transportation.

Q: How many years of industry experience does your company have?

A: Our company boasts over 20 years of industry experience.

Q: How long is the warranty service you provide?

A: We offer a one-year warranty service.

Q: Do you have a professional team of engineers?

A: Indeed, we have a dedicated team of professional engineers.

Q: What is your after-sales service like?

A: We possess a well-established after-sales team that guarantees prompt and efficient service.

Q: Do your products support customization?

A: Absolutely, our products are non-standard and can be tailored to meet customer requirements.

Q: What series of products do you offer?

A: Our products currently encompass seven series: Powder Conveying, Mixing, Fermentation, Baking, Demolding, Cooling, and Material Handling.

Q: What are your main products?

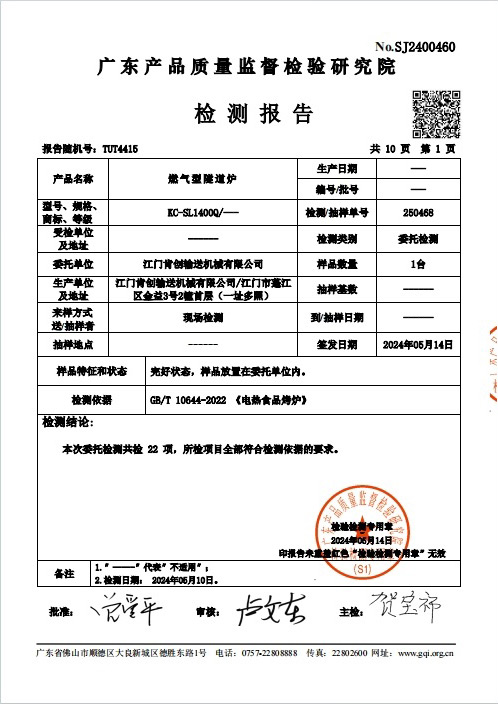

A: Our flagship products include Spiral Cooling Towers, Gas-fired Tunnel Ovens, Demolding Machines, Coating Machines, and Automatic Material Handling Lines.

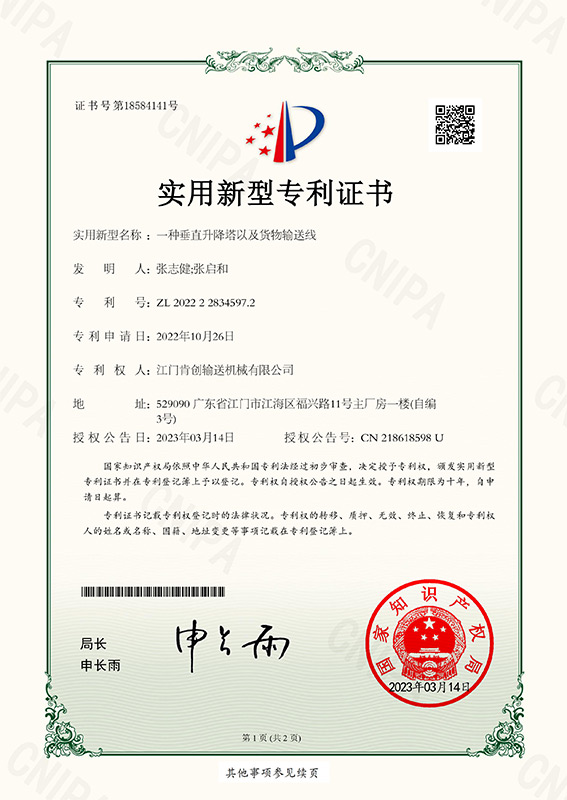

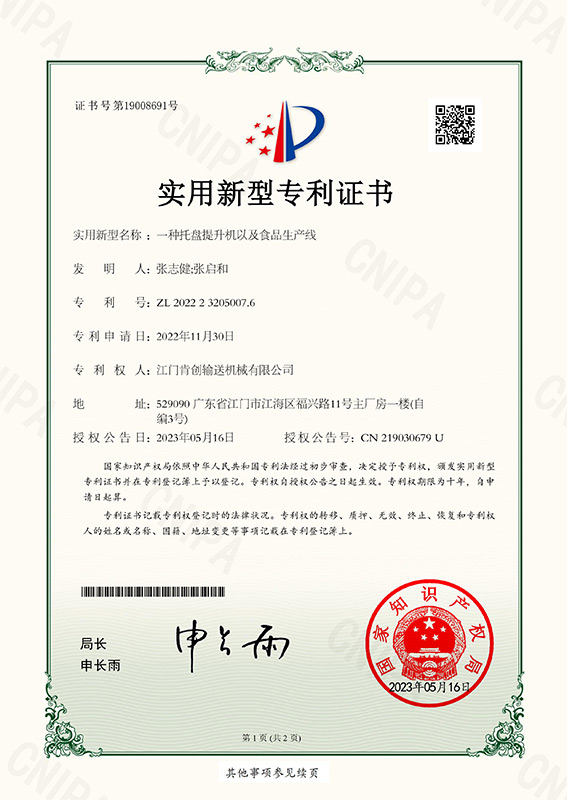

Q: Do you hold any patent certificates?

A: Yes, we possess multiple patent certificates and are committed to technological innovation.

Q: How does your after-sales team handle issues with the products?

A: Our after-sales team promptly addresses any issues and provides solutions, including on-site repairs or replacements as necessary.

Q: Are your products suitable for various food production environments?

A: Our products are designed to be versatile and adaptable to diverse food production settings.

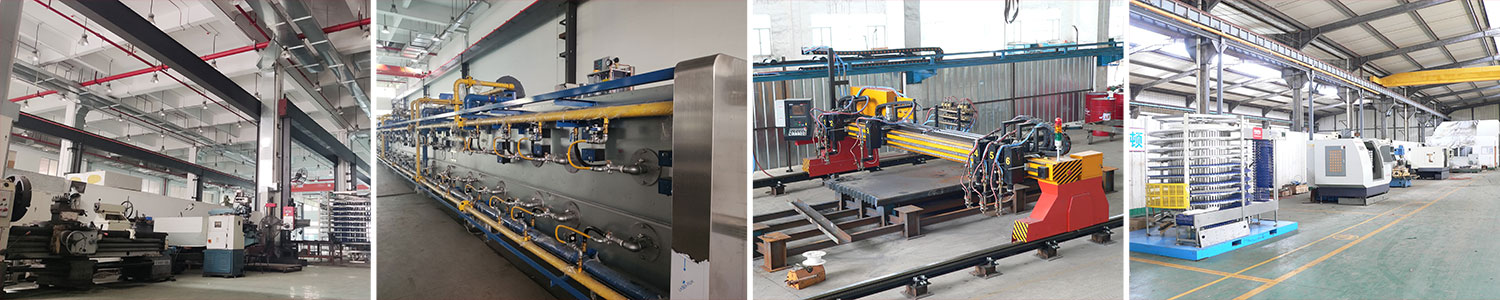

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

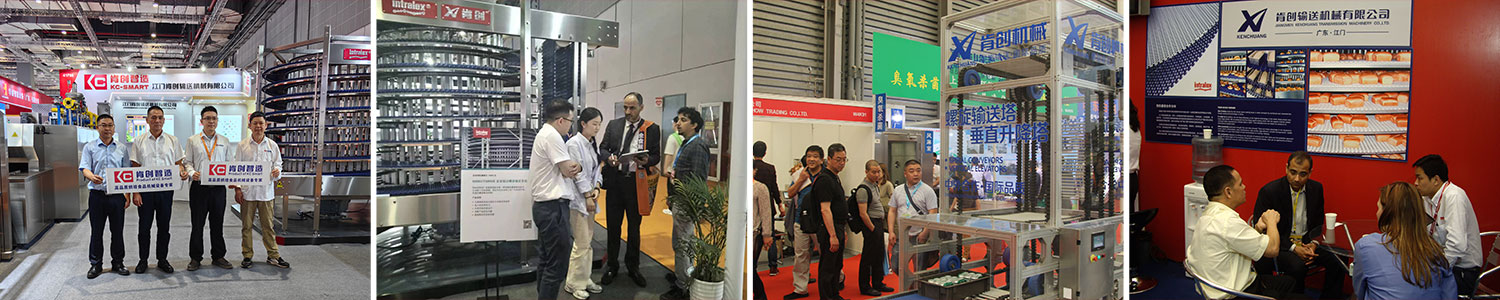

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.