About Us

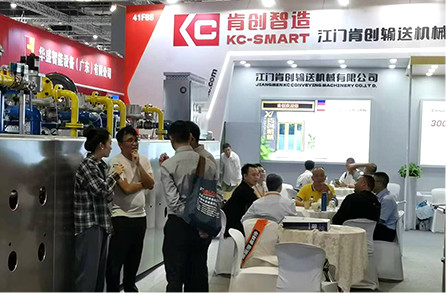

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

View More

Main Products

Why Choose Us?

Info Center

View More

What Is the Difference Between Vertical and Spiral Cooling Towers?

In automated baking lines, “cooling tower” usually means a vertical, enclosed cooling conveyor system that extends dwell time while protecting product quality. KC-SMART focuses on these food-grade cooling towers to help plants hit stable packaging conditions without sacrificing floor space.

How to Maintain a Spiral Cooling Conveyor?

A spiral cooling conveyor is designed to extend product travel time in a compact footprint, so items can stabilize, cool, or buffer between processes without expanding your line length. The trade-off is that more conveying length is packed into one vertical structure, so hygiene access, belt tracking, tension control, and drive health must be managed deliberately.

What Are Automatic Sorting Lines in Bakery Production?

Automatic sorting lines are integrated conveyor-based systems that separate, count, align, and route baked goods into the right lanes for downstream steps such as packing, tray loading, or case packing. In modern bakery plants, they sit after baking and cooling and before primary packaging, acting as a traffic controller that turns mixed product flow into stable, measurable, and pack-ready streams.