Industrial Large Vertical Food Cooling Tower

Vertical Cooling Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Vertical cooling tower/vertical storage lifting tower is an automated production auxiliary equipment for moon-cakes, hamburgers, cakes, baguettes, etc. It aims to extend the transportation time of products in the production line to achieve the purpose of temporary storage or cooling of products. In the cooling process, natural convection or forced convection of air can be used. With small space occupation and relatively low cost, this equipment is an optional choice for food cooling, storage delay and automated transportation. The height of the floor and the tower can be customized according to customers requirements on products and production capacity. As a specialized China vertical food cooling tower manufacturer, we provide a one-stop service that includes customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Industrial Large Vertical Food Cooling Tower Specifications

| Product Name | Vertical Cooling Tower | |||

| Model | KCLT-01 | KCLT-02 | KCLT-03 | KCLT-04 |

| Voltage | 380V3N | 380V3N | 380V3N | 380V3N |

| Power | 6kW | 8kW | 10kW | 12kW |

| Ovenware Size | 400*600 | 400*600 | 400*600 | 400*600 |

Industrial Large Vertical Food Cooling Tower Advantage

KC-SMART is a high-tech enterprise focused on delivering comprehensive solutions for global baking food customers. We offer tailored solutions like the customized vertical food cooling tower, engineered to meet the specific needs of our clients in the baking industry.

1. The cooling tower is made of 304 stainless steel and can accommodate up to 12 trays simultaneously, ensuring high production capacity with minimal vertical space requirements.

2. It boasts a multi-functional design, capable of high-temperature cooling, storage, and fermentation (customization required for fermentation environment).

3. The tower combines manual and automatic operations, providing easy control, silent operation, high stability, and low failure rate.

4. With fully automatic intelligent control and a simple, intuitive touchscreen operation interface, it is highly efficient and energy saving, suitable for continuous batch production.

Industrial Large Vertical Food Cooling Tower FAQ

Q: Can the vertical food cooling tower be customized to fit specific dimensions for my production line?

Yes, our vertical food cooling tower offers complete customization options for its outer dimensions, including the number of layers, layer height, tower diameter, and overall height. This ensures that the tower can be tailored to seamlessly integrate into your unique production line and optimize space utilization.

Q: How versatile is this vertical food cooling tower in terms of its applications?

Our vertical food cooling tower boasts a versatile design, allowing it to serve multiple purposes in a single machine. It can be used for product cooling, storage, and even fermentation processes, providing a cost-effective solution for a range of food production needs.

Q: How does the compact footprint of the vertical food cooling tower benefit my production facility?

The compact design of our vertical food cooling tower maximizes space efficiency in your production facility. By taking up minimal floor area, it frees up valuable real estate for other production equipment or processes. Furthermore, its ability to stack up to 12 trays simultaneously allows for high-volume processing within a compact footprint.

Q: Can I customize the layer configuration of the vertical food cooling tower to suit my specific production requirements?

Absolutely, the layer configuration of our vertical food cooling tower is fully customizable. You can specify the number of layers, layer height, and other dimensions to suit your exact production needs. This flexibility ensures that the tower is tailored to your production workflow, optimizing both efficiency and capacity.

Q: How does the vertical design enhance the productivity of the cooling tower?

The vertical design of our cooling tower contributes to enhanced productivity in several ways. Firstly, by stacking trays vertically, it minimizes the footprint while maximizing the number of trays that can be processed simultaneously. Secondly, the design allows for easy access and loading/unloading of products, streamlining the workflow and reducing downtime. Lastly, the efficient use of space allows for higher throughput and greater overall production capacity.

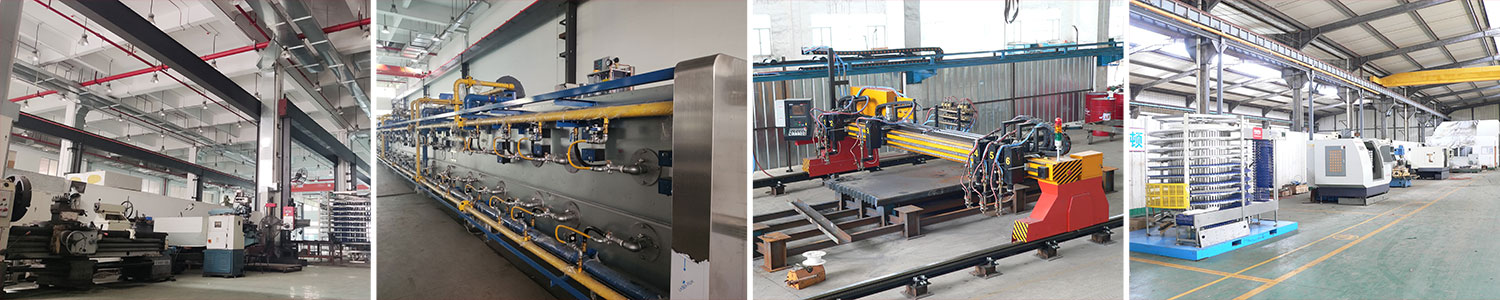

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

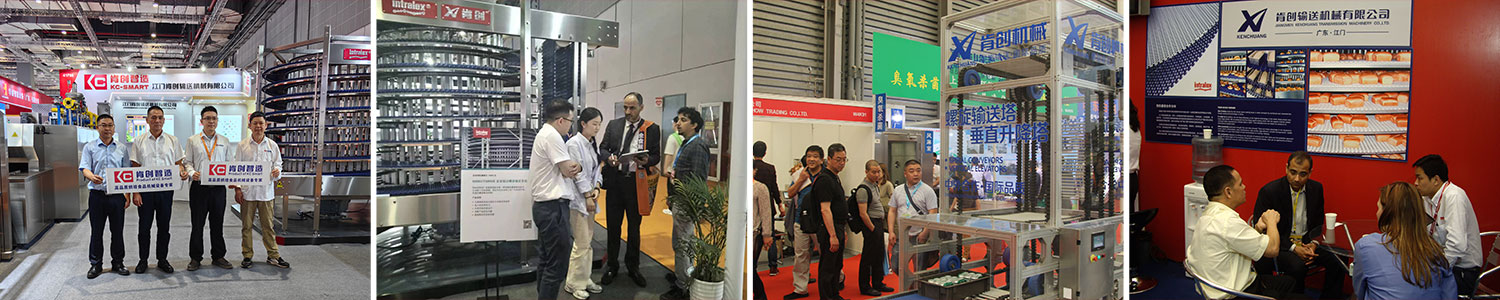

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

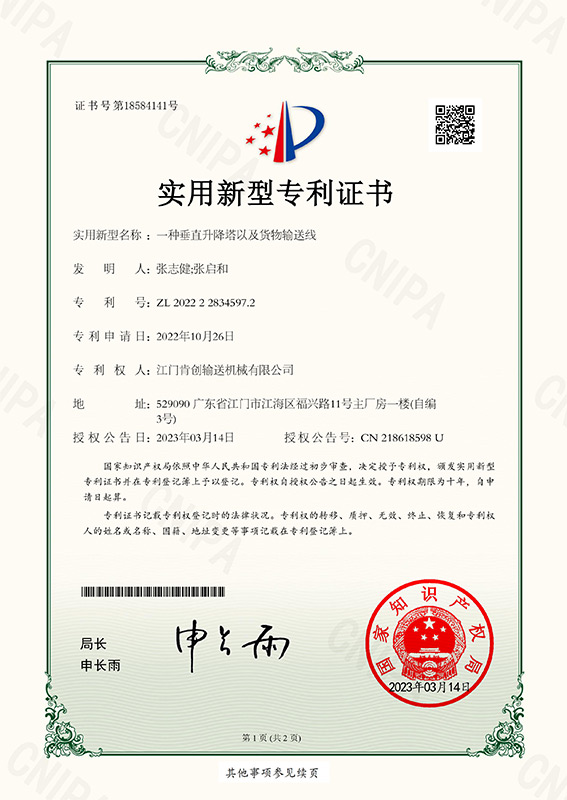

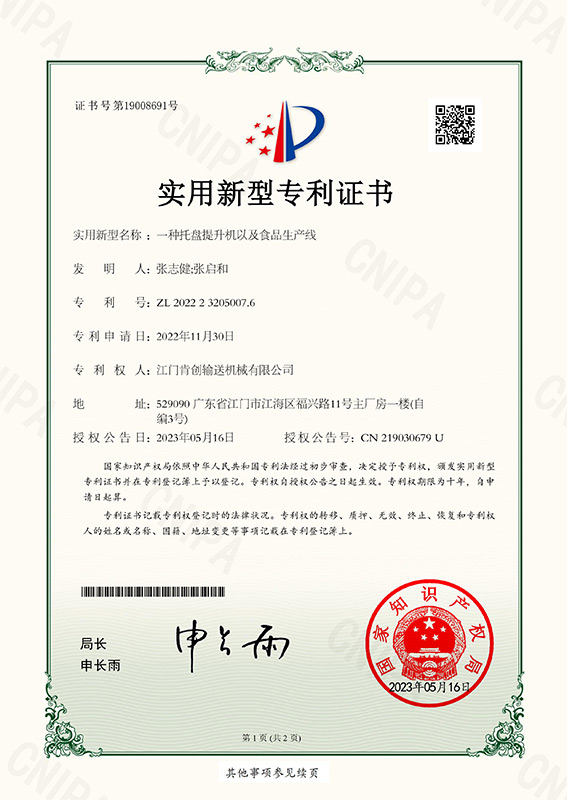

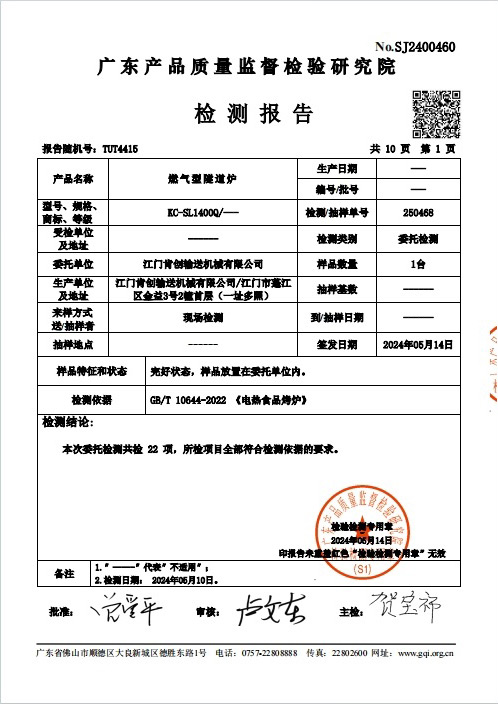

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

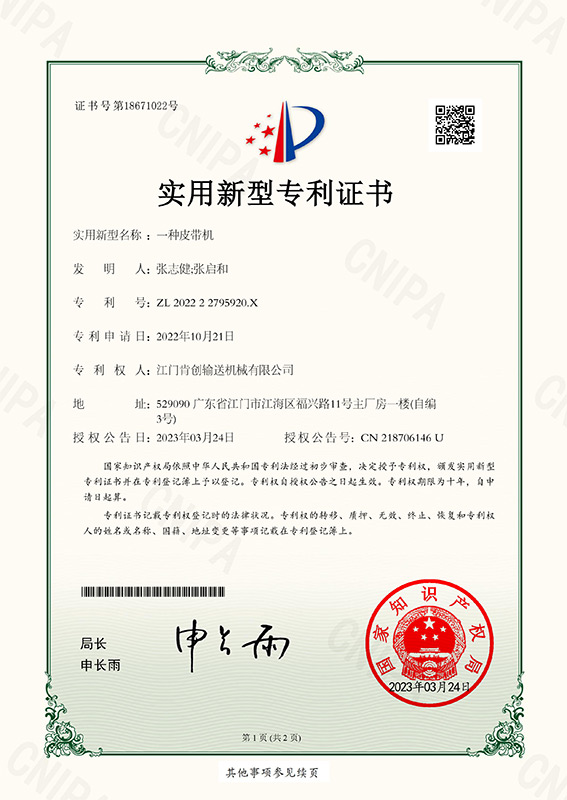

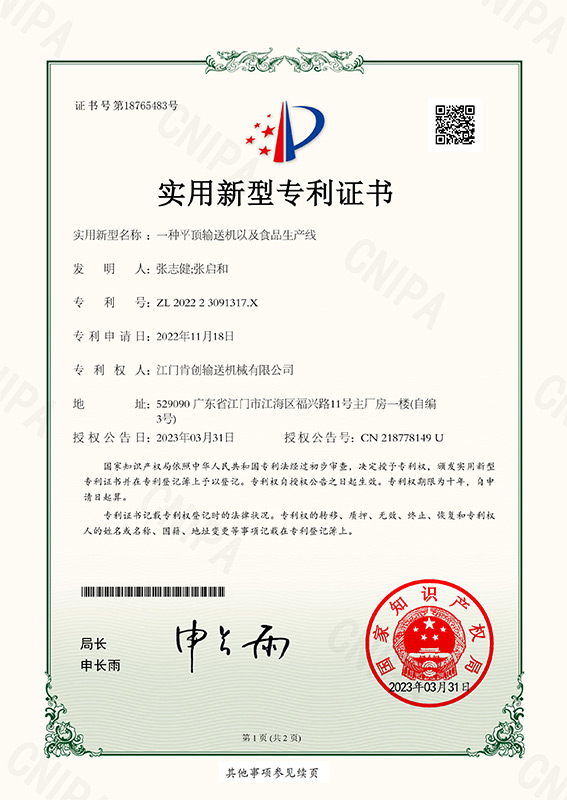

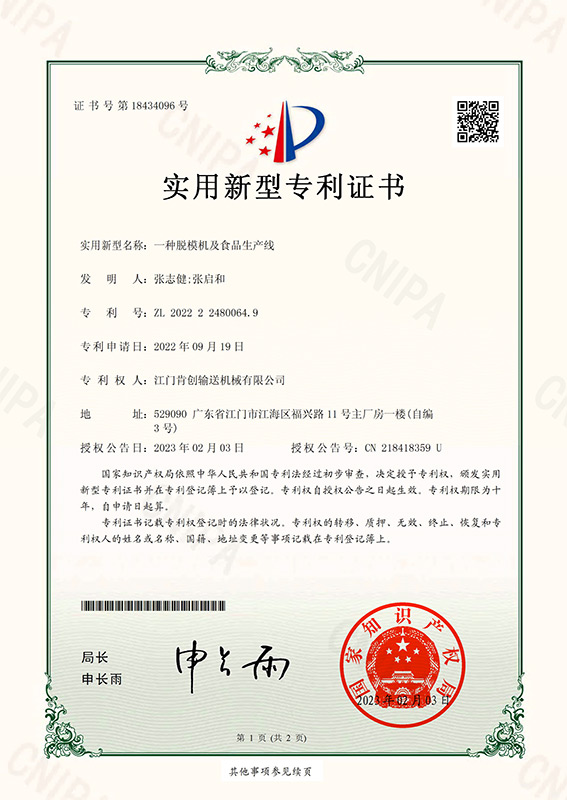

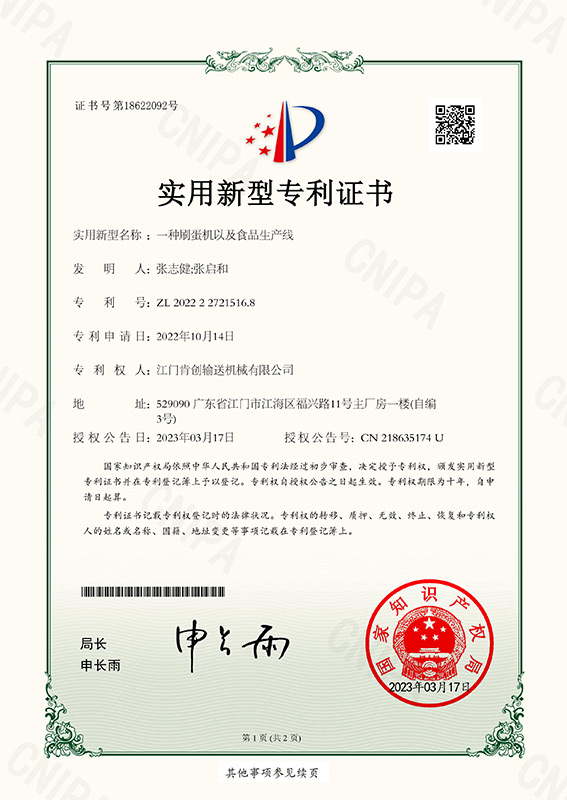

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.