Vertical Air Cooled Cooling Tower

Vertical Cooling Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Air Cooled Cooling Tower is a supporting equipment used for automated production of baked goods. It is mainly used to extend the transportation time of products in the production line, in order to achieve the purpose of temporary storage or cooling of products. In the cooling process, natural convection or forced convection of air can be used to naturally cool or forcibly cool the product during transportation through multi-layer structure and reasonable airflow organization. This type of equipment has a small footprint and relatively low cost, making it an optional solution for food cooling, storage, and delayed delivery automation. It can be customized according to customers' product and production capacity requirements.

Vertical Air Cooled Cooling Tower Parameters

| Product Name | Vertical Cooling Tower | |||

| Model | KCLT-01 | KCLT-02 | KCLT-03 | KCLT-04 |

| Voltage | 380V3N | 380V3N | 380V3N | 380V3N |

| Power | 6kW | 8kW | 10kW | 12kW |

| Ovenware Size | 400*600 | 400*600 | 400*600 | 400*600 |

| OEM/ODM | Accept | |||

| Compay Nature | China Manufacturers Suppliers Factory | |||

Vertical Air Cooled Cooling Tower Features

1. Stainless steel material and high-capacity design

This Air Cooled Cooling Tower is made of 304 stainless steel material, which has good corrosion resistance and food grade safety, ensuring long-term stable use in food production environments. The equipment is designed to be compact and can accommodate up to 12 trays at the same time, enabling efficient production and temporary storage in a small vertical space, meeting the high-capacity needs of large-scale food production enterprises, and improving production efficiency and space utilization.

2. Multi functional integrated design

Equipped with multifunctional features, it integrates high-temperature cooling, storage, and fermentation (fermentation environment needs to be customized). In high-temperature cooling mode, it can quickly reduce the temperature of food and ensure food quality; The storage function can achieve temporary storage of products and flexibly arrange production and packaging processes; The fermentation function (customized) provides a suitable environment for some food products that require fermentation technology, with one machine for multiple uses, improving equipment utilization and production flexibility, and reducing enterprise equipment investment costs.

3. Ergonomic operation design

The Air Cooled Cooling Tower adopts a combination of manual and automatic operation methods, which endows operators with the ability to manually intervene when necessary to cope with emergencies and ensure production safety; It also has an automatic operation mode to achieve automated control of the production process, reducing labor intensity and labor costs. The equipment operates with low noise and a friendly working environment; High stability, low failure rate, reduced production interruption risk, ensuring production continuity and product consistency.

4. Intelligent control system

The Air Cooled Cooling Tower is equipped with a fully automatic intelligent control system, paired with a simple and intuitive touchscreen interface. Operators can easily set and adjust parameters such as temperature, time, and conveying speed to achieve precise process control. The system has automatic alarm and fault diagnosis functions, which can timely detect and solve potential problems. Intelligent control enables efficient and energy-saving operation of equipment, adapts to continuous batch production needs, and improves overall production efficiency and product quality stability.

1. Application in Mooncake Production

In the automated mooncake production line, the Vertical Cooling Tower is a key supporting equipment. After the mooncakes are baked out of the oven, they are forced to cool by air through a cooling tower to quickly reduce the temperature of the mooncakes, prevent residual temperature from causing deformation or excessive flow of the filling, and ensure that the mooncakes form beautifully. The cooled mooncakes can be directly packaged or temporarily stored in the cooling tower, waiting for unified packaging, improving production efficiency and packaging aesthetics, and meeting the large-scale production needs in the Mid-Autumn Festival and other peak sales seasons.

2. Application in Burger Cake Production

Cooling towers also play an important role in the automated production of hamburger cakes. The temperature of freshly baked hamburger cake is relatively high, and direct packaging may affect the packaging quality and product taste. Through the multi-layered conveyor belt of the cooling tower, the hamburger cake is gradually cooled by natural or forced convection, forming a suitable crispy crust on the surface and maintaining a soft and fluffy interior. The cooled hamburger cake can be temporarily stored in the tower, waiting for subsequent packaging or ingredient addition to ensure stable product quality and improve the continuity and flexibility of the production process.

3. Application in Bar Production

On the automated production line of the bar, it can be customized according to the production rhythm and cooling requirements of the bar. The body of the baguette is relatively large and the cooling time is relatively long. The cooling tower is designed with reasonable layers and heights to provide sufficient cooling space for the baguette. During the cooling process, natural or forced convection of air takes away the heat from the surface and interior of the bread, gradually cooling and shaping the dough, forming a unique hard shell on the surface, and the internal tissue is delicate and elastic. The cooled rod can be directly stored in the temporary storage area, waiting for packaging or delivery to ensure that the quality of the product is not affected during transportation and sales.

4. Applications in the Production of Other Baked Goods

In addition to the common baked goods mentioned above, Air Cooled Cooling Tower can also be widely used in the automated production of various baked goods such as biscuits, cookies, pastries, etc. For foods of different shapes, sizes, and processing requirements, cooling towers can meet their specific cooling needs by adjusting parameters such as wind speed, number of layers, and conveying speed. In some food production processes that require fermentation technology, customized cooling towers can provide a suitable fermentation environment, achieve the integration of cooling, storage, and fermentation, improve production efficiency and equipment utilization, and save space and costs for enterprises.

Vertical Air Cooled Cooling Tower Maintenance

1. Daily cleaning and inspection

After each production is completed, the inside and outside of the cooling tower should be cleaned in a timely manner. Use a soft cloth or brush to remove dust, flour, and other residues from the surface of the equipment, in order to prevent accumulation and affect the equipment's heat dissipation and hygiene. Check if there are any foreign objects wrapped or damaged in the transmission components such as conveyor belts and chains, and clean and repair them in a timely manner. At the same time, check whether the connection parts of the equipment are loose. If there is any looseness, it should be tightened in a timely manner to ensure stable operation of the equipment.

2. Maintenance of cooling system

Regularly check the operation status of the cooling fan, including wind speed, air volume, and fan noise. If any abnormalities are found in the fan, the dust on the fan blades should be cleaned in a timely manner, the fan bearings should be checked for good lubrication, and lubricants should be added or replaced if necessary. For cooling towers that use forced convection, it is necessary to regularly check whether the air ducts are unobstructed and whether there is any air leakage to ensure uniform and stable cooling effect.

3. Maintenance of transmission system

Regularly maintain transmission components such as conveyor belts and chains. Check the tension of the conveyor belt, and adjust the tensioning device in a timely manner if any looseness is found; The chain needs to be regularly lubricated to reduce wear and extend its service life. At the same time, check whether the operating current and voltage of the transmission motor are normal, whether there is abnormal heating or noise. If there is any abnormality, it should be repaired or replaced in a timely manner to ensure the normal operation of the transmission system.

4. Electrical system inspection

Regularly inspect the electrical control system of the equipment, including wires, cables, wiring terminals, etc., to ensure that the connections are secure, free from looseness, short circuits, or aging. Check whether the buttons, switches, sensors and other components on the control panel are sensitive and reliable. If there are any abnormalities, they should be repaired or replaced in a timely manner. At the same time, backup and update the intelligent control system to ensure stable software operation and avoid production interruptions caused by system failures.

5. Regular comprehensive maintenance

Perform comprehensive maintenance on the cooling tower at regular intervals (such as three months or six months). This includes deep cleaning of the entire equipment, checking the wear and tear of all components, and replacing damaged or aging parts. Conduct comprehensive testing and debugging of the cooling, transmission, electrical and other systems of the equipment to ensure that each system operates normally and meets performance standards. At the same time, calibrate the operating parameters of the equipment, such as temperature, time, wind speed, etc., to ensure precise control of the production process.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

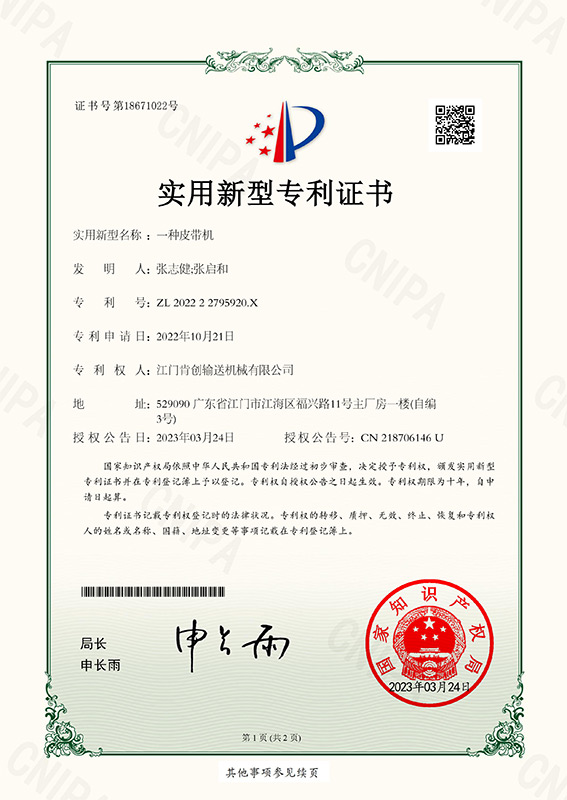

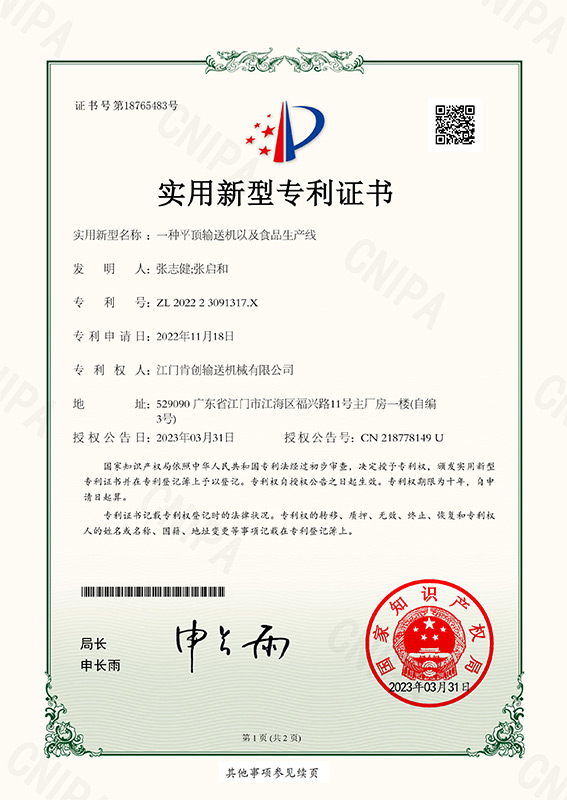

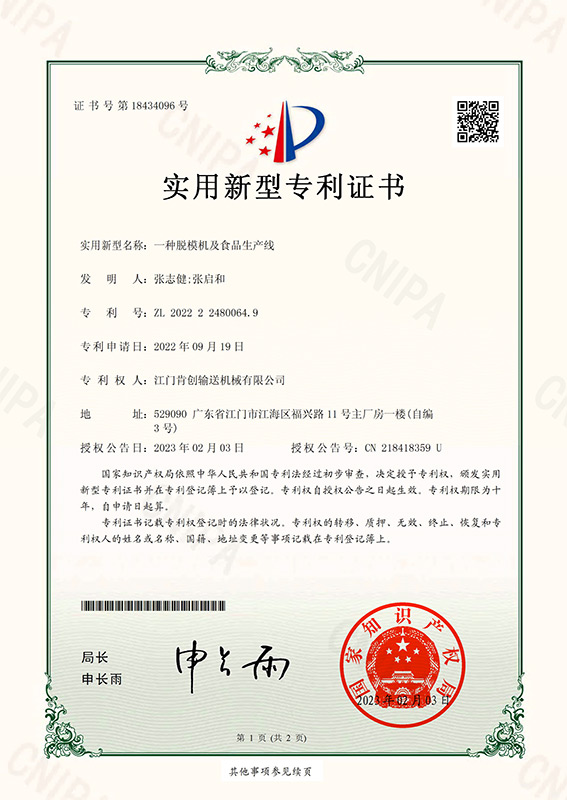

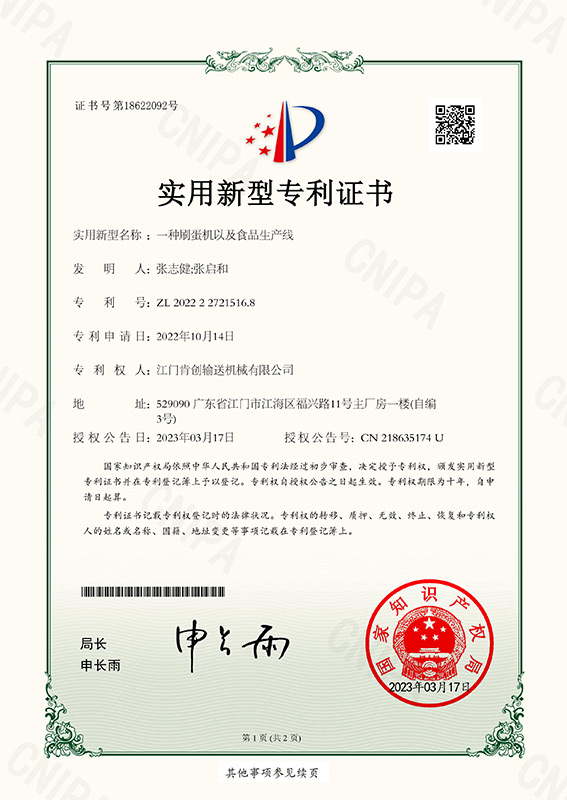

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.