Bakery Spiral Cooler

Spiral Conveyor Cooling Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Bakery Spiral Cooler is an efficient cooling device specifically designed for the baking industry, mainly used for rapid cooling of baked goods such as bread, cakes, mooncakes, etc. after they are baked. By increasing the cooling area through multi-layer rotating conveyor belts, using a blower to drive air flow, and combining with a water circulation heat exchange system to achieve uniform cooling. When the equipment is working, high-temperature food is evenly distributed on each layer of conveyor belt and slowly rotated in a controlled temperature and humidity environment to ensure synchronous cooling of the surface and interior, avoiding cracking or collapse.

Bakery Spiral Cooler Parameters

| Product Name | Spiral Conveyor Cooling Tower | |

| Model | KCLX-01 | KCLX-02 |

| Voltage | 380V3N | 380V3N |

| Power | 3kW | 6kW |

| Conveyor Material | POM/Stainless steel | POM/Stainless steel |

| Rotational Speed | 1.6/2.0/2.2/2.5/3.2 | 1.6/2.0/2.2/2.5/3.2 |

| OEM/ODM | Accept | |

| Compay Nature | China Manufacturers Suppliers Factory | |

Bakery Spiral Cooler Features

1. Food grade safe materials

Spiral Cooler adopts a 304 stainless steel frame combined with high-strength food grade plastic conveyor belt, which is wear-resistant and corrosion-resistant, with a smooth and non stick surface, eliminating the risk of metal foreign objects. The conveyor belt has been certified by the US FDA and meets international food safety standards. It can directly come into contact with baked goods to ensure production hygiene.

2. Multi functional integrated design

One machine achieves triple functions of high-temperature product cooling, short-term storage, and dough fermentation (fermentation requires customized environment), and the working mode can be switched through parameter adjustment. Accurate temperature control and water retention in the cooling section, constant temperature preservation in the storage section, and adjustable temperature and humidity in the fermentation section to meet the needs of the entire baking process.

3. Intelligent dual-mode control system

Support manual/automatic integrated operation, daily production can be set with fully automatic programs, and manual intervention can be provided when special needs arise. Equipped with a silent motor and shock-absorbing design, it has low operating noise, with a 7 × 24-hour continuous working stability of 99.8% and a failure rate of less than 0.5%.

4. Visualized intelligent control

Spiral Cooler adopts an industrial grade touch screen interface, which displays real-time temperature and humidity curves, equipment status and other data. Built in 10 sets of process formula storage, supports one click calling, can preset parameters such as cooling time and wind speed, and achieve standardized production. The energy-saving mode automatically optimizes energy consumption, saving 30% of electricity compared to traditional devices.

5. Efficient continuous production capacity

The multi-layer spiral structure maximizes the utilization of space, and a single tower can process 1500-2000 baked goods per hour. Conveyor belt variable frequency speed regulation, combined with intelligent queuing system, achieves continuous and uninterrupted cooling of products, eliminates production bottlenecks, and improves overall production line efficiency by more than 40%.

6. Customized design

The equipment can be customized according to the customer's production capacity requirements and production space limitations, including adjustments to the number of layers, layer height, tower diameter, and tower height. This flexibility ensures that the equipment can perfectly adapt to production needs of different scales, achieving optimal production efficiency and space utilization.

Bakery Spiral Cooler Application

1. Cooling of baked goods

This device is designed specifically for high-temperature baked goods such as bread, cakes, mooncakes, etc. By accurately controlling the cooling rate, it ensures a smooth transition of the product from a high-temperature state. Its unique spiral structure extends the cooling path, allowing hot air to circulate fully, avoiding deformation or deterioration of taste caused by local overheating of the product, perfectly locking in the aroma and soft texture of baked goods.

2. Food storage and preservation

As a multifunctional storage solution, the spiral cooling tower provides a constant temperature and humidity environment, creating an ideal preservation space for baking semi-finished or finished products. In this environment, the freshness of the product is extended, and the color, taste, and nutritional content are maximally preserved, providing a buffer for flexible production planning and ensuring consistent product quality.

3. Dough fermentation environment

By integrating temperature and humidity control modules, this device can transform into a professional dough fermentation chamber. The spiral conveyor belt rotates slowly, coupled with adjustable temperature and humidity parameters, creating uniform fermentation conditions for the dough. Whether it's the long-term low-temperature fermentation of European bread or the rapid rise of pizza dough, precise control can be achieved to improve fermentation efficiency and dough quality.

4. Automated production line connection

In modern baking production lines, Bakery Spiral Cooler serves as the core hub, seamlessly connecting the front-end oven with the back-end packaging equipment. Its intelligent conveying system automatically adjusts the speed according to the front-end production capacity, achieving full process automation of "baking cooling packaging". This coherent operation mode not only significantly improves production efficiency, but also reduces manual intervention, lowers pollution risks, and ensures smooth and hygienic production processes.

5. Multi category flexible production

The Bakery Spiral Cooler has high production flexibility and can easily meet the cooling needs of different baked goods. Through simple parameter adjustments, the optimal cooling solution can be found for both puff pastry that requires rapid heat dissipation and soft bread that requires gentle cooling. This flexible production capability enables a single device to support mixed production of multiple categories, maximizing equipment utilization and meeting diverse market demands.

6. Standardized operation of central kitchen

For chain baking enterprises or large food factories, spiral cooling towers are the key to achieving standardized production. Its centralized cooling and packaging capabilities ensure that every batch of products undergoes strict quality control and maintains a unified high standard. In conjunction with the cold chain distribution system, this equipment supports large-scale and long-distance product supply, helping enterprises expand their markets and enhance brand competitiveness.

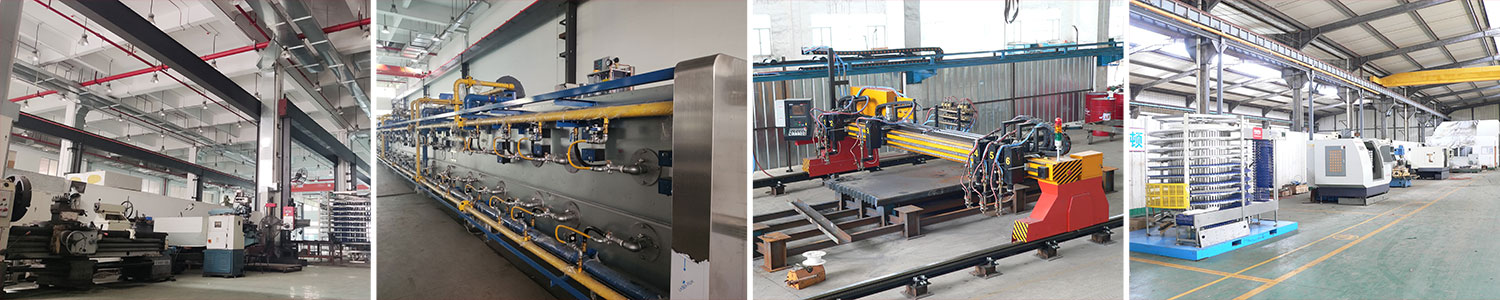

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

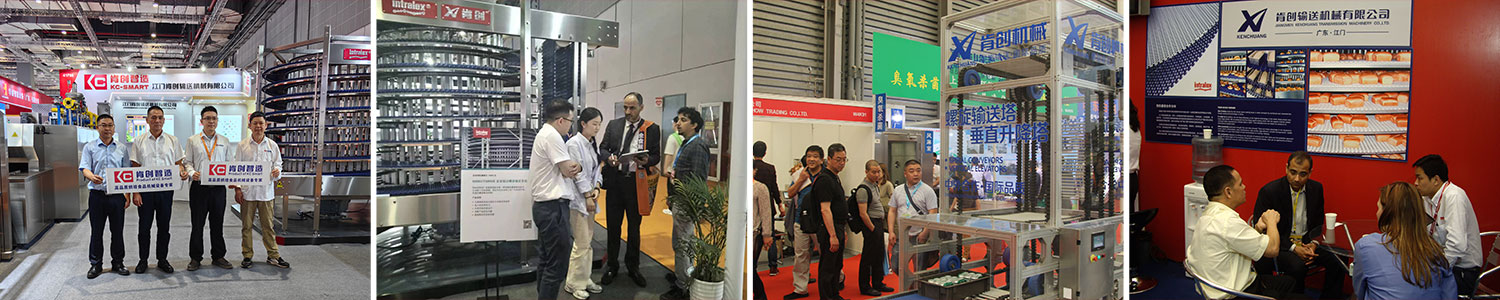

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

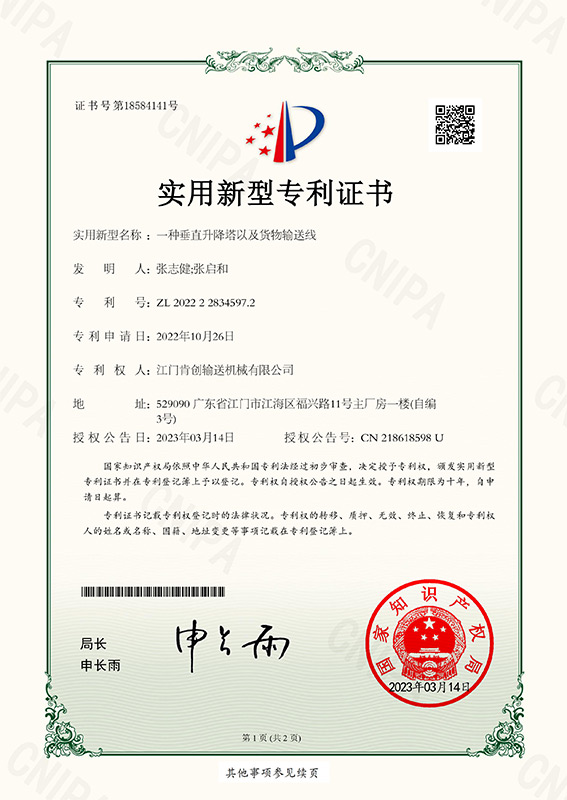

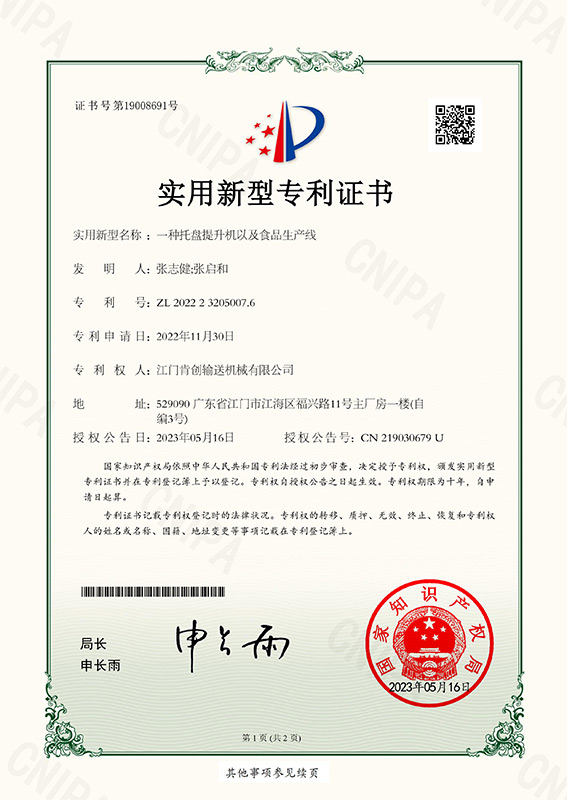

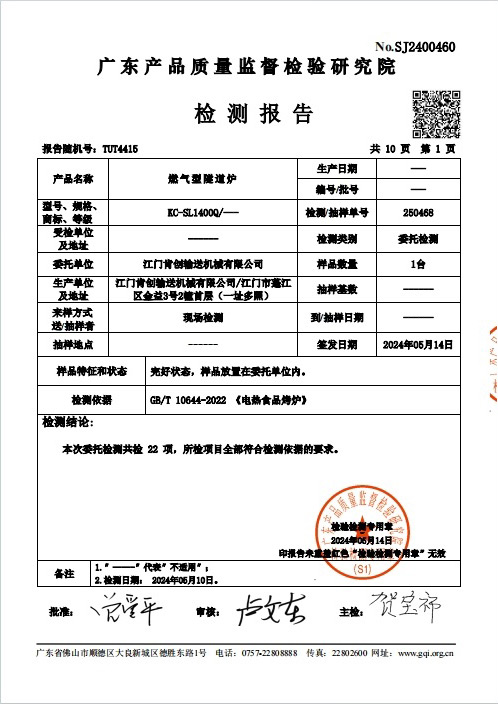

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.