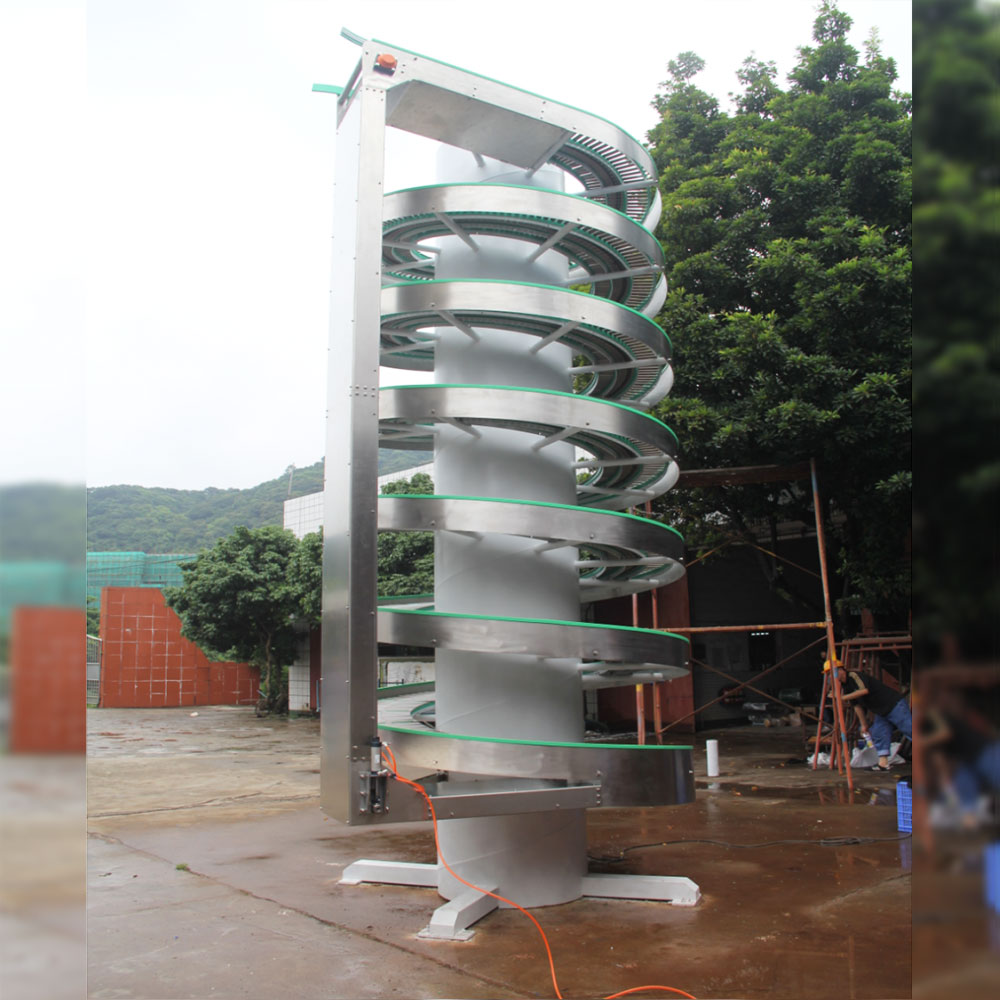

Fully Automatic Spiral Vertical Conveyor

Pillar Rotary Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Spiral Vertical Conveyor is a device that efficiently transports materials vertically within a limited space. It uses a spiral conveyor path and motor-driven conveyor belts or chains to continuously and stably transport materials between different floors or heights.

Fully Automatic Spiral Vertical Conveyor Specifications

| Product Name | Fully Automatic Spiral Vertical Conveyor |

| Model | KC-ZSX-01 |

| Voltage | 380V3N |

| Power | 1.5kW |

| Width | 1000-3000 |

| Height | 1000-10000 |

| Conveyor Material | POM |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

Fully Automatic Spiral Vertical Conveyor Advantage

1. High performance conveyor belt material

The conveyor belt of Spiral Vertical Conveyor is made of high-strength food grade plastic and logistics transportation plastic materials, which have many advantages. Food grade plastic conveyor belts comply with food hygiene standards, are wear-resistant, corrosion-resistant, have a smooth and easy to clean surface, do not stick to products, ensure that food is not contaminated during transportation, and maintain the integrity of the product surface. Plastic conveyor belts for logistics transportation have higher strength and durability, and can withstand the transportation of heavy materials, adapting to different working conditions.

2. Multi functionality and space saving

This device has multifunctionality, capable of conveying products both upwards and downwards, and occupies minimal space. By designing the conveying path reasonably, products can be transported stably and quickly inside the tower, greatly saving material transportation time and improving production efficiency. Meanwhile, its compact structural design enables it to flexibly integrate into various production lines, effectively solving the problem of limited space.

3. Intelligent control system

Equipped with a fully automatic intelligent control system and a simple and intuitive touch screen operation interface. Operators can easily set and adjust parameters such as conveying speed and time to achieve precise process control. The system has automatic alarm and fault diagnosis functions, which can timely detect and solve potential problems, reducing downtime. Intelligent control enables efficient and energy-saving operation of equipment, adapts to batch and continuous production needs, and improves overall production efficiency.

1. Application in the food industry

Spiral Vertical Conveyor plays an important role in automated production lines for mooncakes, hamburgers, cakes, and other food products. Taking mooncake production as an example, the temperature of freshly baked mooncakes is relatively high. They can be quickly transported to the cooling area through a cylindrical rotating tower to avoid deformation or affecting the taste due to prolonged stacking. In the production of hamburgers and cakes, this equipment can efficiently transfer materials between different processing stages, improve production efficiency, and ensure the freshness and quality of products.

2. Application in the pharmaceutical industry

In the process of drug production, Spiral Vertical Conveyor can be used for the transportation of drug raw materials, packaging and transportation of finished drugs, and other links. Its food grade material and stability ensure the hygiene and safety of drugs during transportation, avoiding cross contamination. At the same time, the intelligent control of the equipment can be integrated with the drug production management system to achieve traceability and quality control of the production process.

3. Application in the daily necessities industry

For the production of daily necessities such as detergents and cosmetics, Spiral Vertical Conveyor can meet the material transportation needs between workshops on different floors. For example, in detergent production, raw materials can be transported from the storage area to the processing area, and then the finished products can be transported to the packaging area to improve the continuity and efficiency of the production process. In cosmetics production, this equipment can ensure gentle delivery of products and avoid damage to their appearance.

4. Application in the electronic and electrical industry

In the production line of electronic components and household appliances, it can also be used for the transportation and assembly of small parts. Its stable and fast conveying performance ensures the rhythm of the production line and improves production efficiency. At the same time, the compact design of the equipment can adapt to the flexible and varied layout of production lines in the electronics and electrical industry, saving valuable production space.

5. Other industry applications

In addition to the above-mentioned industries, it can also be widely applied in multiple fields such as agriculture, chemical industry, logistics and warehousing. In the field of agriculture, it can be used for the transportation of materials such as seeds and fertilizers; In the chemical industry, it can be used for the transportation of chemical raw materials and products; In logistics warehousing, it can be used as a solution for lifting and transporting goods, achieving material circulation between different shelf layers and improving warehousing and distribution efficiency.

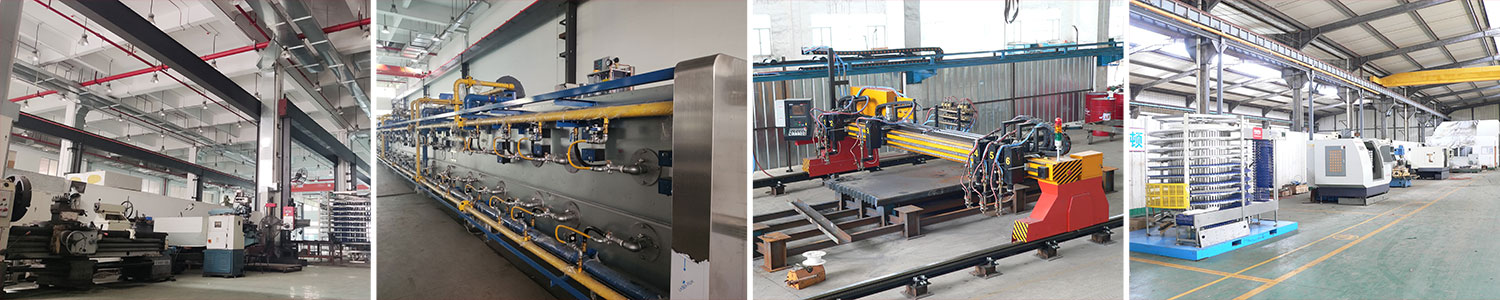

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

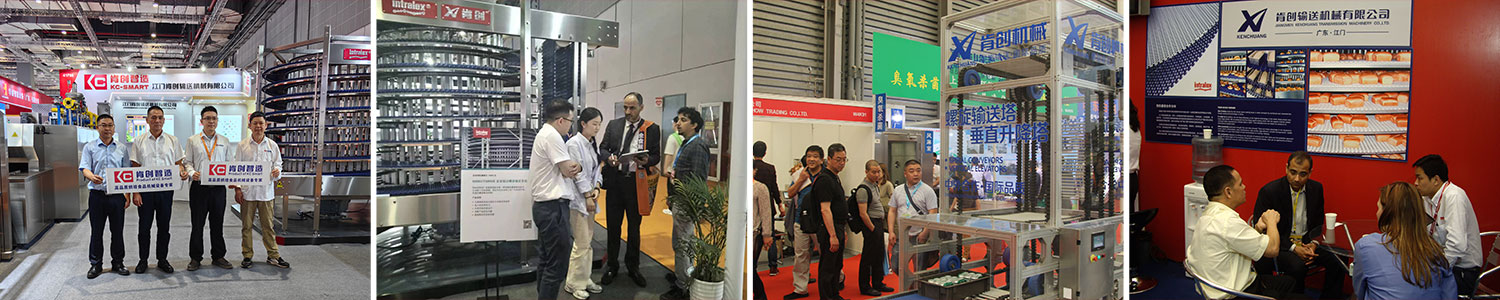

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

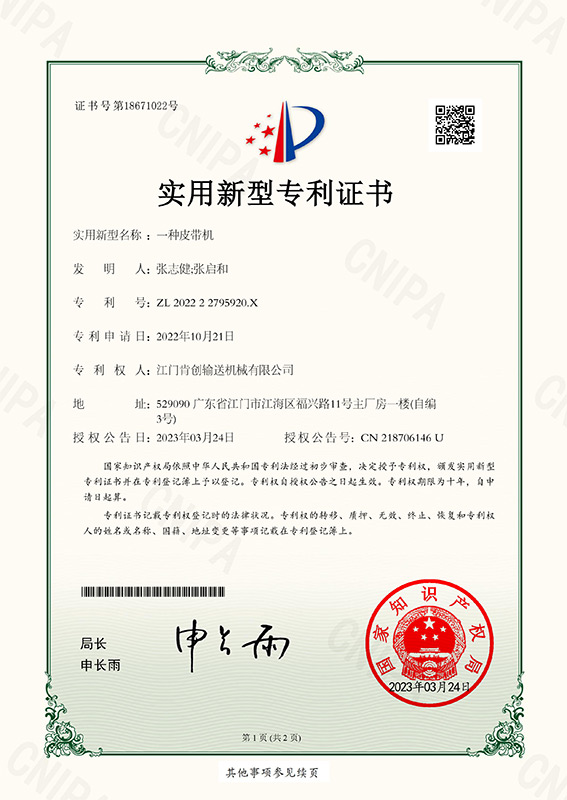

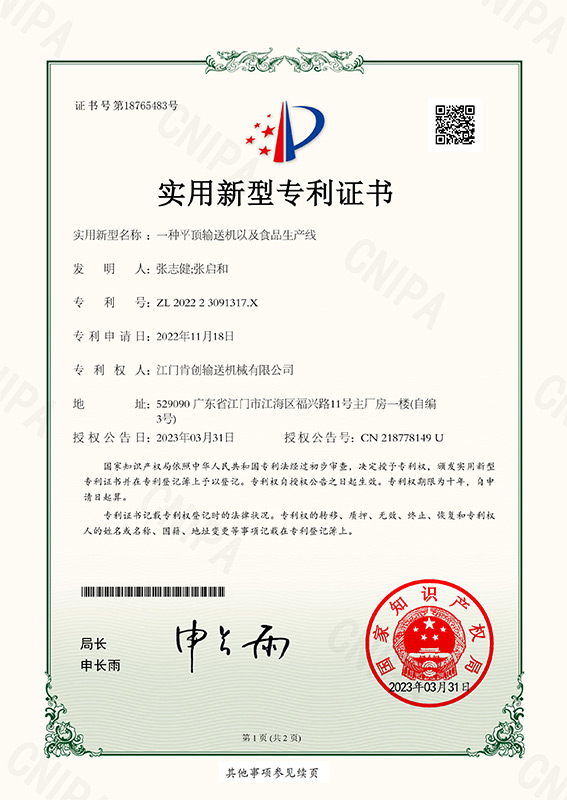

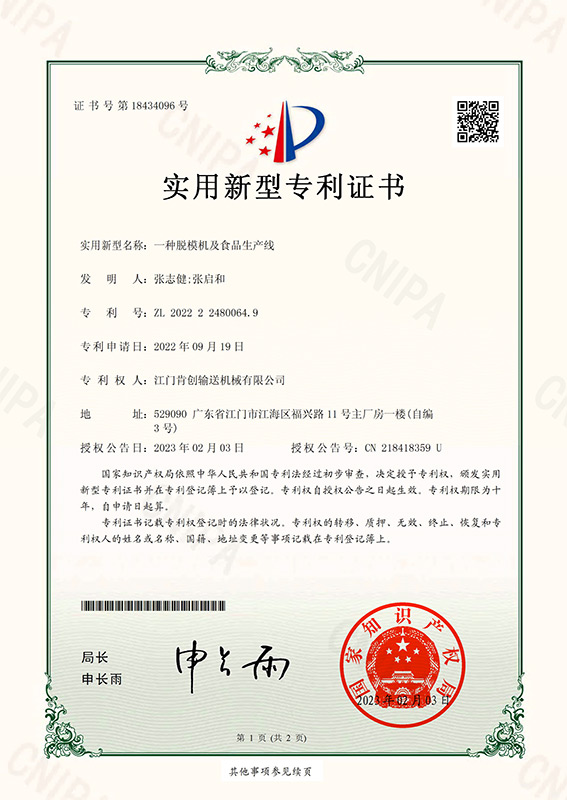

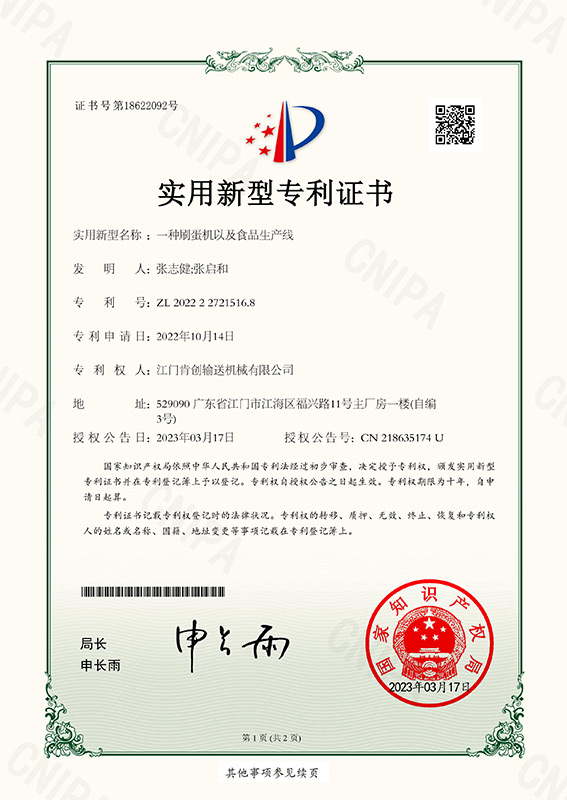

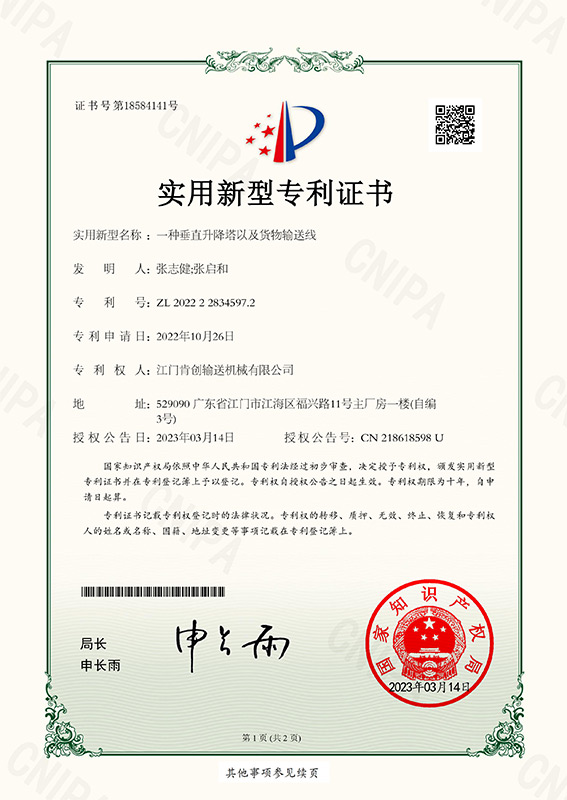

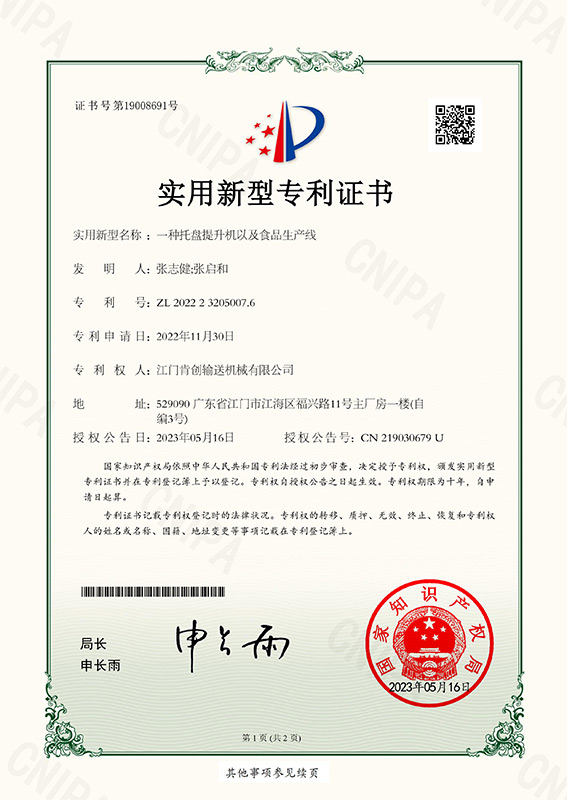

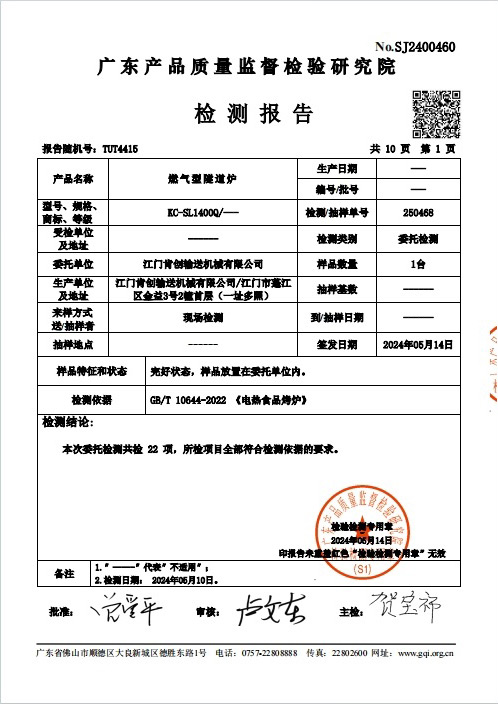

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.