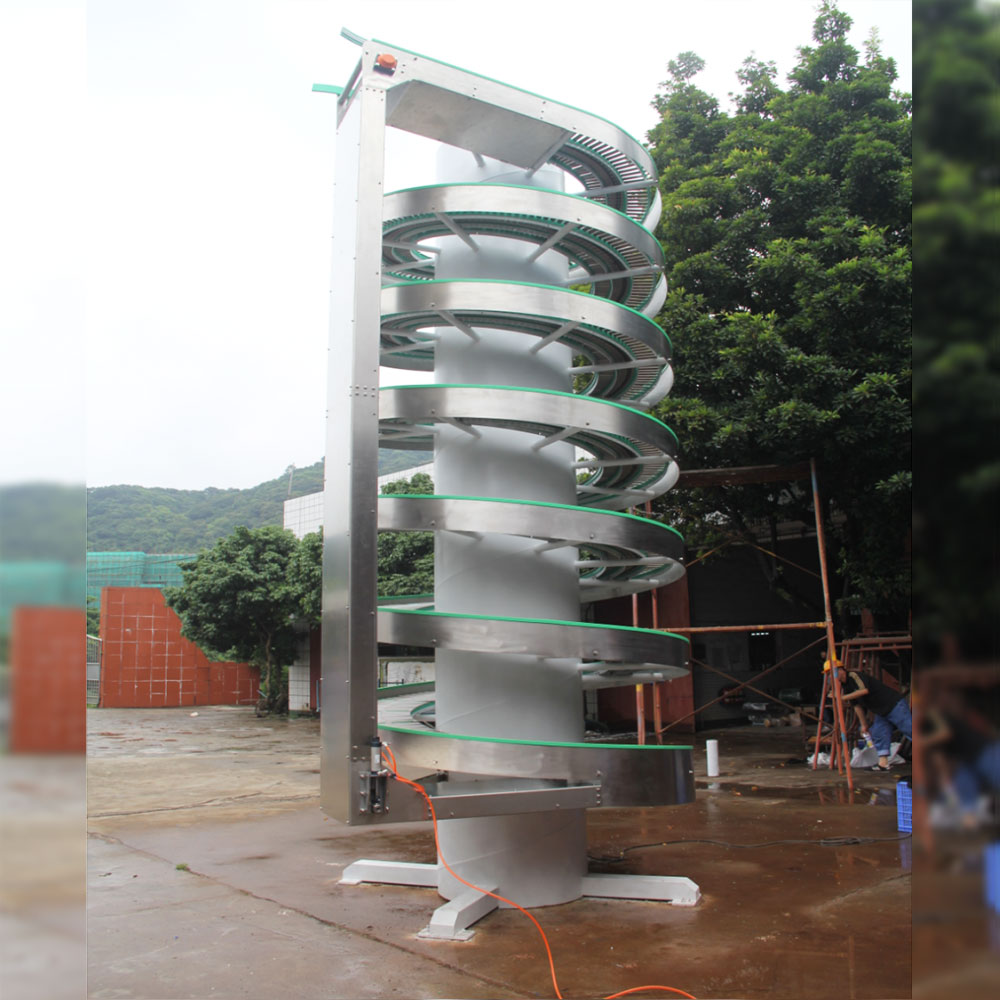

Vertical Spiral Belt Conveyor

Pillar Rotary Tower

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Spiral Belt Conveyor is an efficient and compact material conveying device designed for design scenarios that require vertical or small space conveying of materials. Its core structure includes driving devices (such as electric motors, reducers, and couplings), spiral blades, bearing systems, material troughs, and inlet and outlet ports. Its working principle is that after the material is added from the feeding port, it moves upward along the bottom of the material trough under the rotation of the spiral blades. By relying on the frictional force between the material and the groove wall, as well as the pushing force of the blades, stable conveying can be achieved.

Vertical Spiral Belt Conveyor Parameters

| Product Name | Vertical Spiral Belt Conveyor |

| Model | KC-ZSX-01 |

| Voltage | 380V3N |

| Power | 1.5kW |

| Width | 1000-3000 |

| Height | 1000-10000 |

| Conveyor Material | POM |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

Vertical Spiral Belt Conveyor Features

1. High quality materials, safe and durable

Food grade material: The conveyor belt is made of high-strength food grade plastic, which meets food hygiene standards and ensures the safety of direct contact with food. The special material makes the conveyor belt have good corrosion resistance and wear resistance, and can operate stably for a long time in various complex environments. Smooth surface, not easy to adhere to materials, easy to clean, while avoiding surface damage and maintaining product integrity.

2. One machine for multiple uses, saving space

Multi functional integration: The device has the function of one machine with multiple uses, which can meet the transportation needs of various materials. Small footprint, suitable for production environments with limited space, improving space utilization. Support stable and efficient upward or downward transportation of products, effectively saving transportation time and improving production efficiency.

3. Flexible operation, stable and reliable

Manual and automatic integrated design, flexible operation, meeting different production needs. Adopting advanced noise reduction technology to ensure low operating noise and provide a comfortable working environment. The equipment structure is stable, with a low failure rate, ensuring long-term stable operation and reducing downtime for maintenance.

4. Intelligent control, efficient and energy-saving

Equipped with a fully automatic intelligent control system to achieve unmanned operation and improve production efficiency. Adopting a touch screen operation interface, simple and intuitive, easy to operate and maintain. Optimize equipment energy consumption, achieve high efficiency and energy saving, reduce production costs, and meet the needs of batch continuous production.

5. Flexible customization to meet needs

We can customize parameters such as number of floors, height, tower diameter, and tower height according to customer production capacity requirements to meet different production needs. Through customized design, the equipment can flexibly adapt to various production scenarios and provide the best solutions.

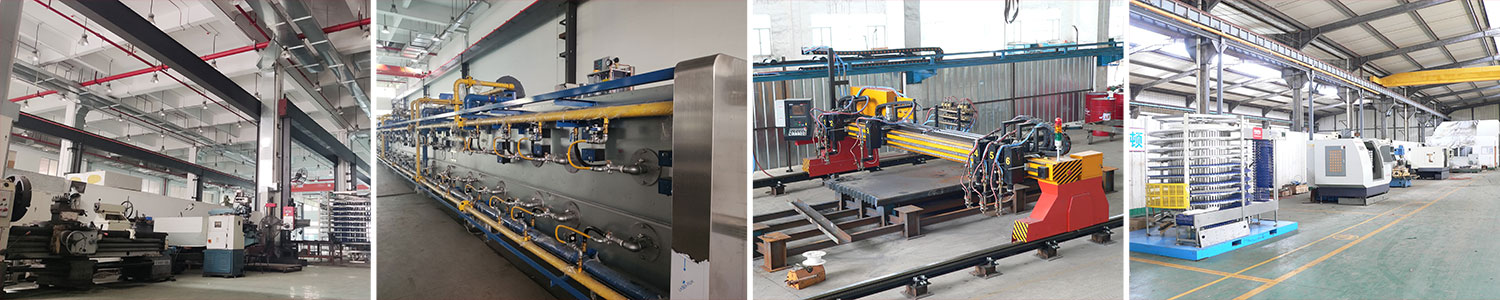

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

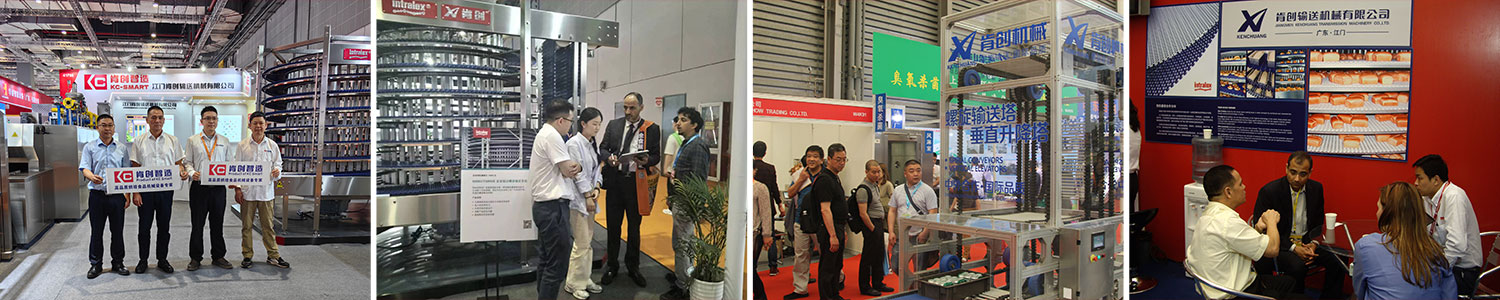

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

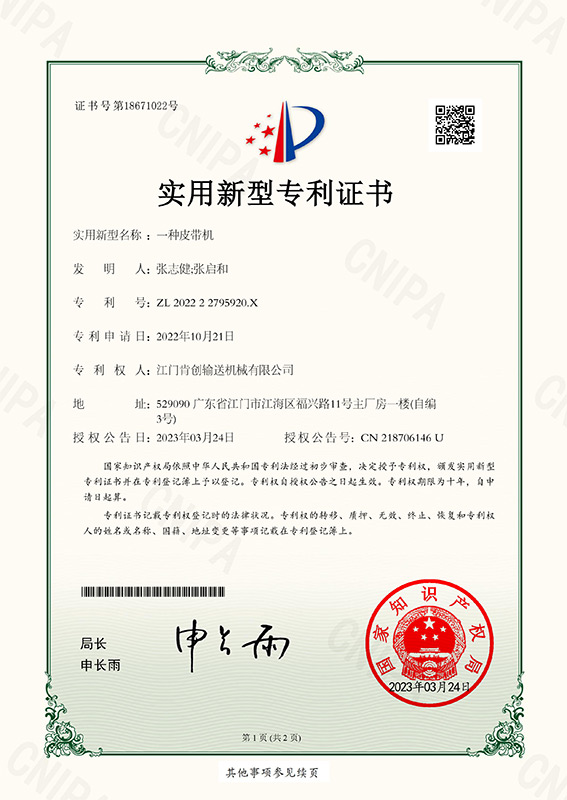

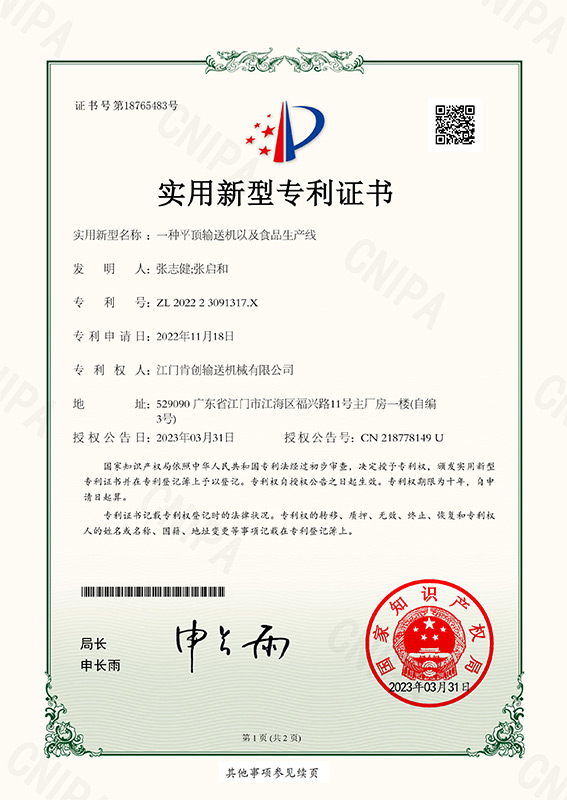

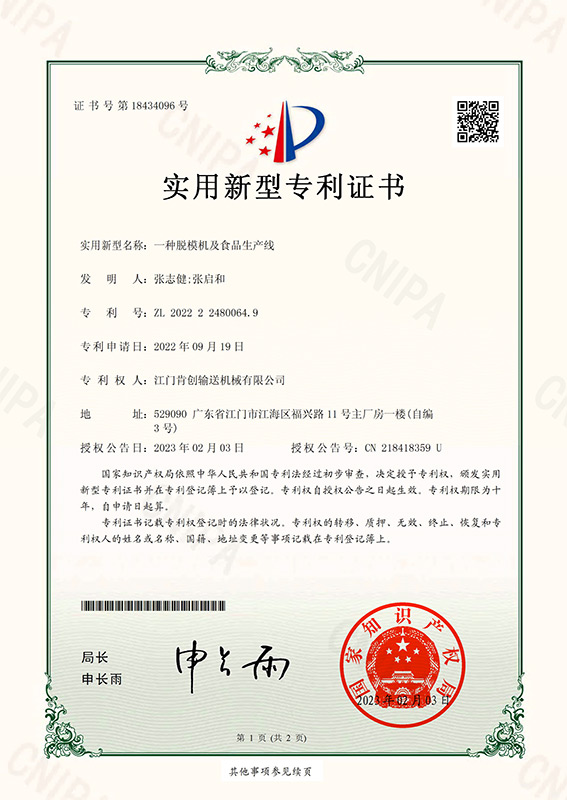

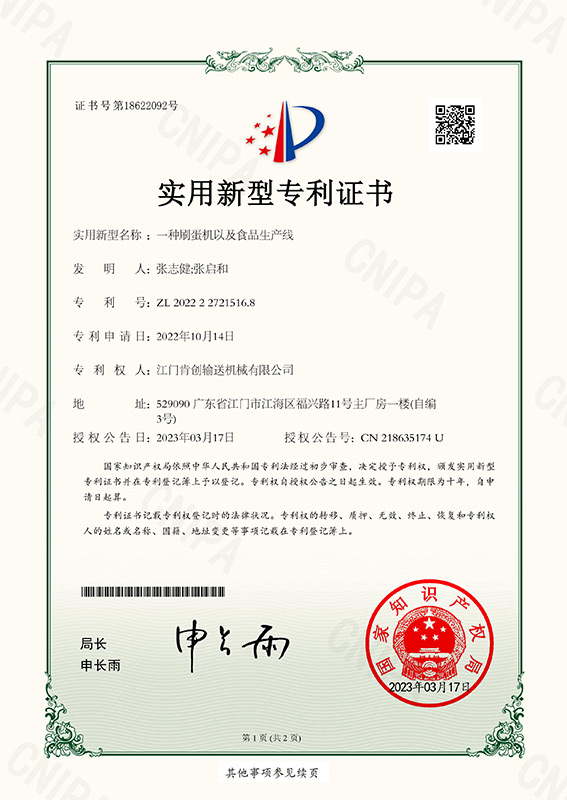

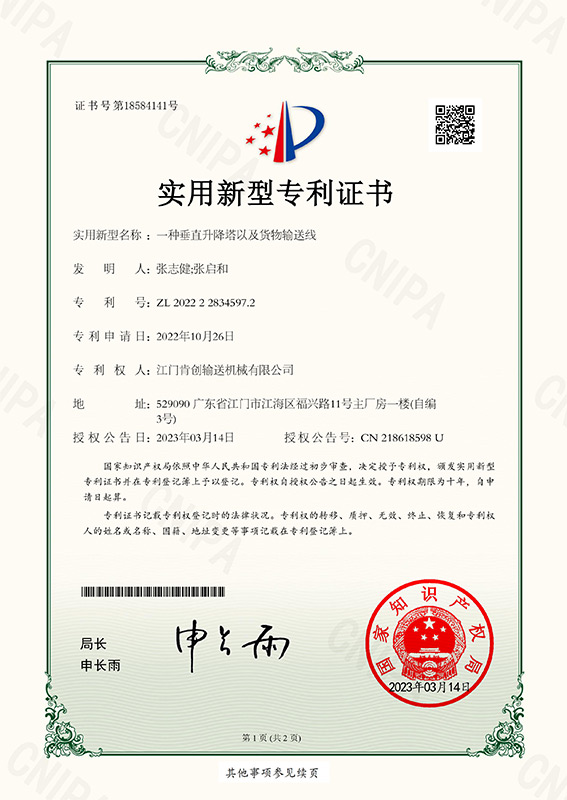

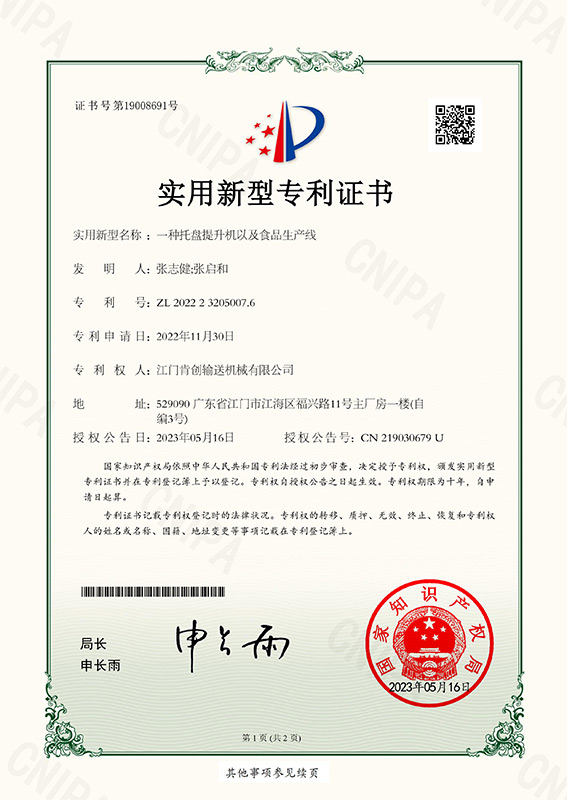

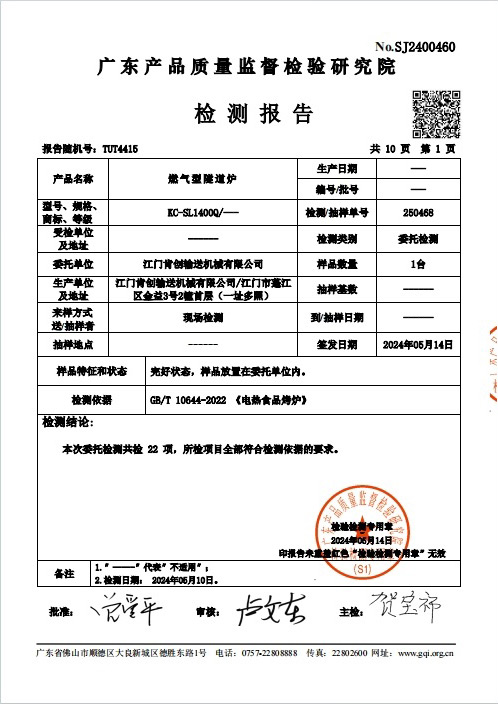

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.