Egg Liquid Automatic Liquid Applicator

Liquid Brushing Applicator

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

The automatic liquid applicator is a supporting equipment for the production of mooncakes, pastries, and other food items. It can be connected to a conveyor line or tunnel oven to complete the automatic liquid coating process. Featuring a servo control system, it provides even and rapid coating, and can be customized according to the customer's production capacity requirements. Among our offerings is the customized automatic liquid applicator, a specialized solution tailored for precise, efficient application processes in the food production line. As a leading China automatic liquid applicator supplier, KC-SMART dedicated to providing one-stop solutions for global baking food customers.

Egg Liquid Automatic Liquid Applicator Specifications

| Product Name | Liquid Applicator | |

| Model | KCSJ-2 | KCSJ-4 |

| Power | 1.5kW | 3kW |

| Size | 2990*920*2070mm | 2990*1580*2070mm |

| Brush Quantity | 2 | 4 |

Egg Liquid Automatic Liquid Applicator Advantage

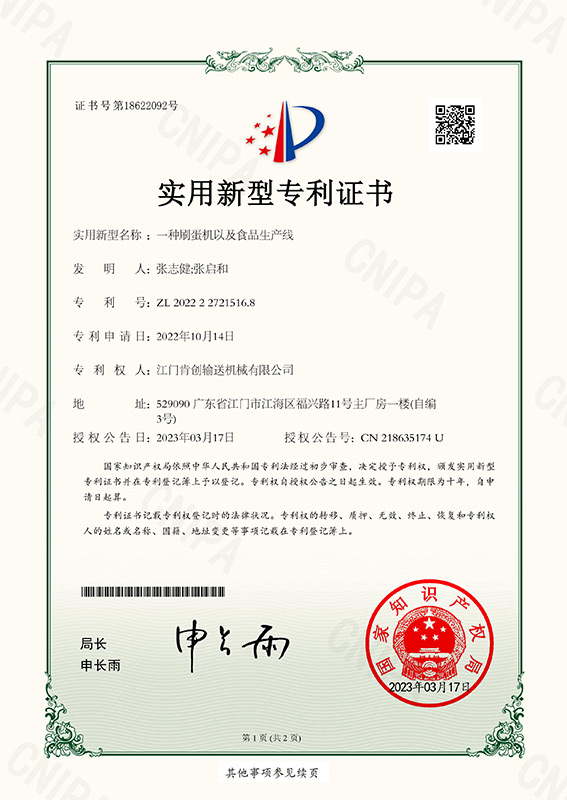

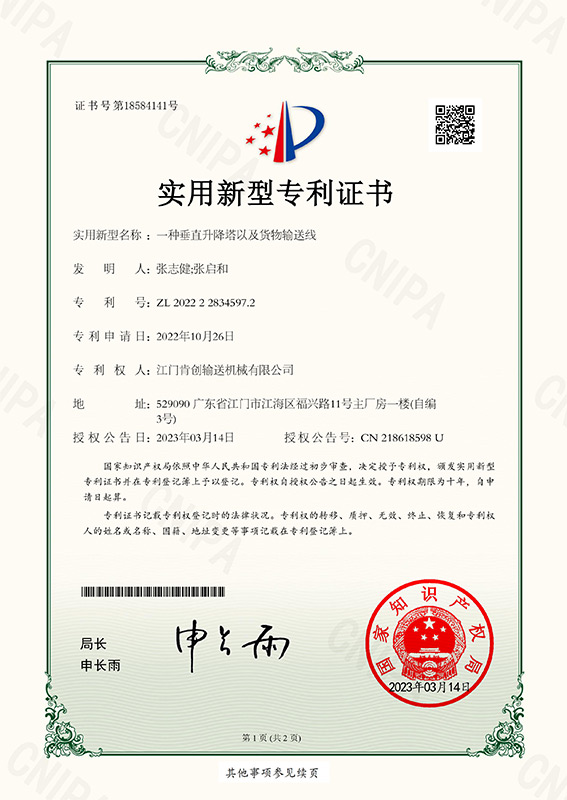

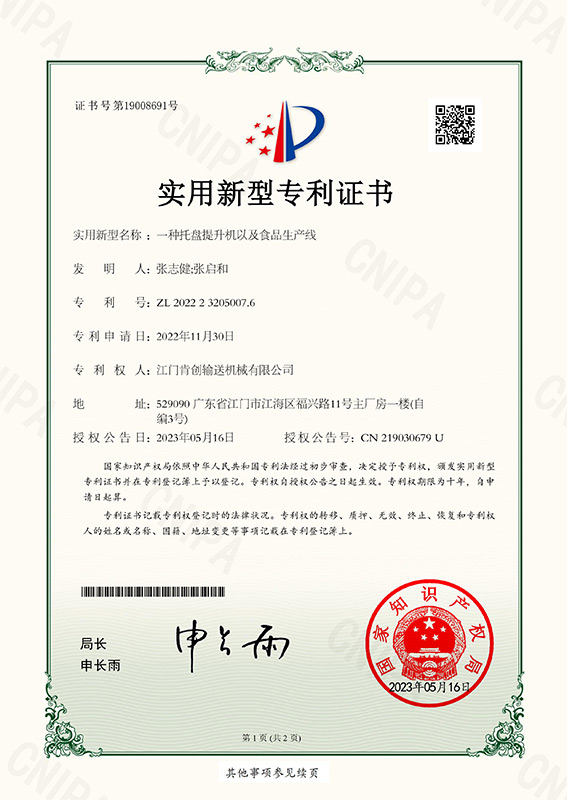

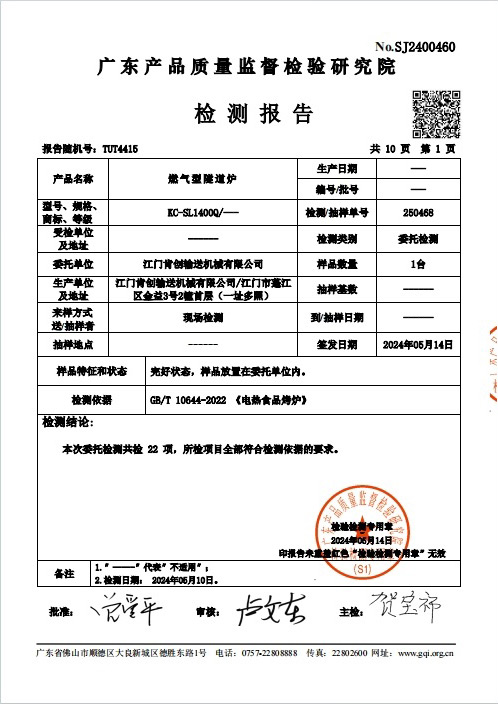

1.The equipment is designed and produced independently, with autonomous programming, and holds a patent certificate for the equipment.

2.Frame: Constructed with aluminum profiles, it features a simple yet sturdy structure that is convenient for relocation and disassembly.

3.Workstations: Divided into four independent workstations with separate controls, they address the issue of inconsistent front-to-back positioning when double troys enter the liquid coating area.

4.Motors: The equipment is equipped with 20 motors, which separately control the X-axis, Z-axis, and brushes. The advantage lies in the independent control of each ink making it suitable for diverse product operating conditions. Additionally, it solves the issue of conventional liquid applicators where the brush encounters the high temperature edge of the baking tray during operation due to the tray's edge being higher than the product, resulting in poor coating effect.

5.Horizontal Guide Rails: in the X-axis direction (the direction of the baking tray's movement), a rail-based movement system is employed, driven by a motor and controlled by a serve system. This avoids issues commonly found in conventional liquid applicators,such as powder generation from fiction of the timing belt,bet breakage, excessive vibration, high noise levels, short service life, and difficulty in maintenance.

6.Vertical Guide Rails: in the Z-axis direction (vertical up and down movement), a rail based movement system is employed, driven by a motor and controlled by a servo system. It can be adjusted according to the height of different products to achieve the best performance and results.

7.Brush: Customized brand, motor-driven, servo-controlled, with quick disassembly function for easy maintenance and cleaning, and with rotation function to ensure the evenness of coating liquid.

8.Liquid Coating Tray: Made of stainless steel, the tray is equipped with adjustable tension wires at the top to scrape of excess liquid coating, ensuring coating effectiveness while preventing splashing from the brush during rotation. The bottom section features a cooling water circulation unit are installed separately, allowing the tray to be removed individually for convenient cleaning and maintenance.

9. Electrical Control: An independent stainless steel electrical box with autonomous programming and Delta servo control is equipped. The touchscreen display offers multiple recipes, suitable for various products. Users can select different recipes based on the production of different products, and can also fine-tune various date on the touchscreen to adjust the products sightly. Sensors are installed on both sides of the equipment to track the baking trays, solving the issue of inconsistent front-to-back positioning when double trays enter the liquid coating area.

Egg Liquid Automatic Liquid Applicator FAQ

Q: What food processing processes is your automatic liquid applicator mainly used for?

A: Our automatic liquid applicator is mainly used in various food processing processes that require liquid coating, such as brushing egg liquid onto mooncakes, as well as other foods that need uniform liquid coating.

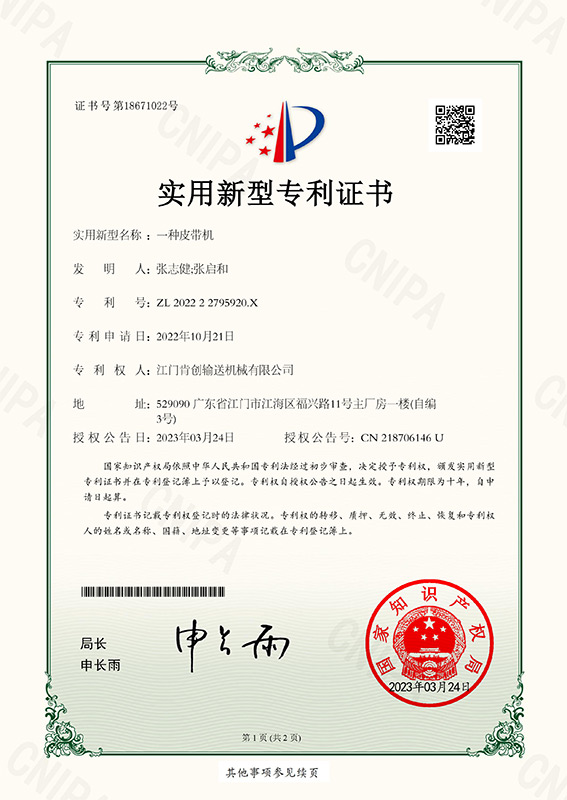

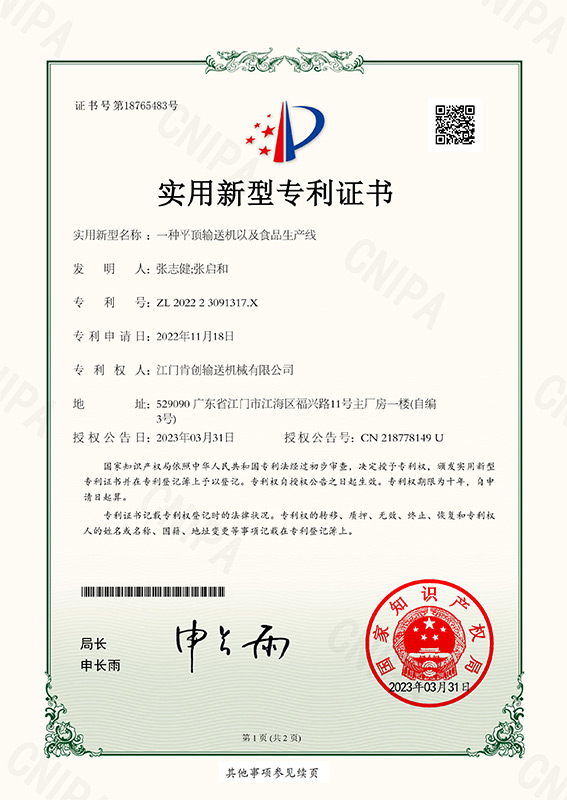

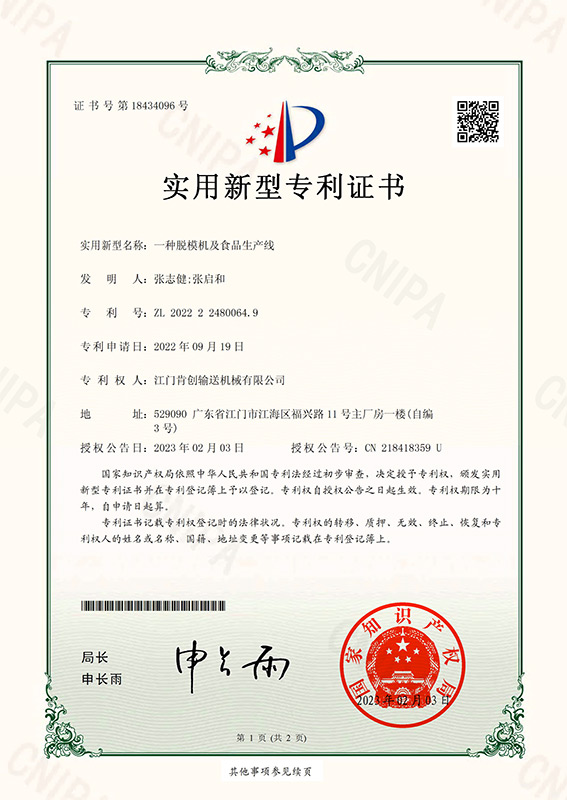

Q: Is this automatic liquid applicator self-developed by your company? Is it protected by patents?

A: Yes, this automatic liquid applicator is self-developed by our company and has obtained a patent certificate, with full intellectual property rights.

Q: If my production line has special size requirements, can you customize it?

A: Absolutely, our automatic liquid applicator supports customized sizes and can be designed and manufactured according to your specific needs.

Q: How effective is the liquid coating using this brushing machine?

A: Our brushing machine adopts an advanced design that ensures uniform and rapid liquid coating, improving production efficiency while guaranteeing food quality.

Q: Is it convenient to maintain and relocate this automatic liquid applicator?

A: Yes, our automatic liquid applicator is designed with a simple maintenance structure that allows users to easily perform routine maintenance and servicing. Additionally, relocation and disassembly are also very straightforward, facilitating movement between different production lines or venues.

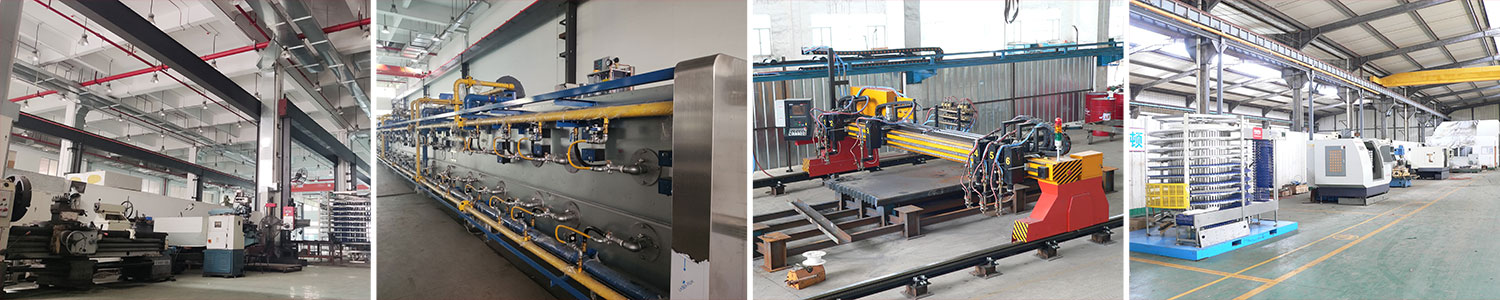

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

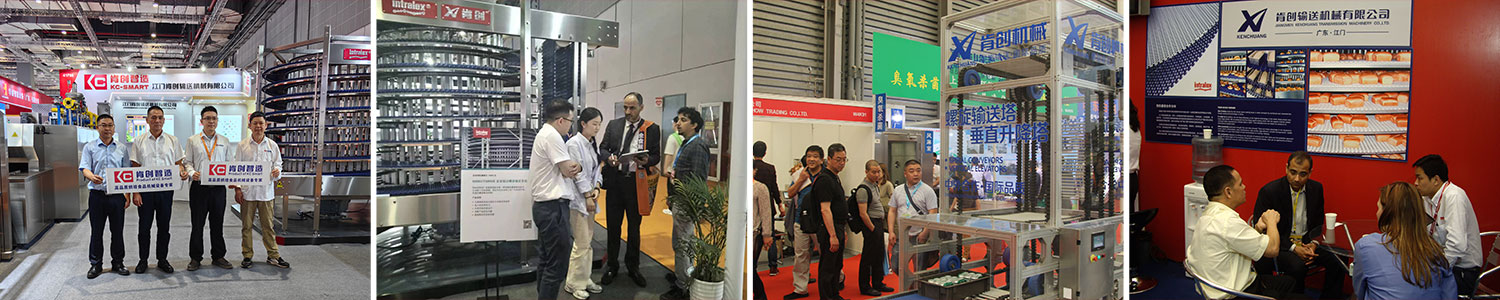

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.