Stainless Steel Idustrial Horizontal Dough Mixer

Horizontal Mixer

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

A variety of mixers are available to suit different types of dough, such as hamburgers, toast, European-style panels, pizza, Mexican crusts, Chinese pastries, frozen dough, etc. The all-stainless steel body and open structure design are easy to clean and maintain. The main motor is controlled by frequency conservation, and the direct drive provides optimal mixing speed control for the horizontal dough mixer. The cylinder turning motor is directly driven, which is more hygienic and reliable compared to traditional hydraulic cylinder turning systems or chain cylinder turning devices. The PLC control system is equipped with a display screen human-machine interface to achieve recipe management and more flexible and convenient daily operations. The unique cooling jacket design makes the cooling efficient and the mixing tank has a longer service life. With years of experience as a China horizontal dough mixer manufacturer, we are dedicated to producing reliable, durable, and efficient dough mixers tailored to the baking industry's unique demands.

Stainless Steel Idustrial Horizontal Dough Mixer Specifications

| Product Name | Horizontal Mixer | |||

| Product Code | KCWJ-400 | KCWJ-600 | KCWJ-800 | KCWJ-1000 |

| Material | Stainless Steel | |||

| Type | Direct Drive Services | |||

| Application Scenarios | Dough Production | |||

| Production capacity | 150kg | 250kg | 350kg | 450kg |

| Voltage | 380V3N | 380V3N | 380V3N | 380V3N |

| Power | 20kW | 30kW | 45kW | 55kW |

Stainless Steel Idustrial Horizontal Dough Mixer Advantage

The customized horizontal dough mixer offers versatile configurations in capacity, mixing speed, and control systems, catering to diverse needs in the baking and food processing industry.

1. Heavy-duty stainless steel open frame design.

2. Stainless steel feed inlet for flour, middle seed, liquid sugar, oil,etc.

3. Turning angle of 0-120°.

4. High-strength stainless steel main shaft and agitator.

5. Unique shaft seal design avoids the risk of internal leakage of contaminants.

6. Equipped with stainless steel steel folding roads for higher mixing efficiency.

7. Motor direct-drive cylinder turning system.

8. Compared to traditional vertical mixers, it is more efficient. It has a larger mixing capacity. It is convenient for discharging. The dough quality is stable with a cooling jacket. The surface temperature is controllable. It has stable operation and long service life.

9. Compared to low-end horizontal mixers, it has a longer service life. It is easy to clean. It has a fully stainless steel frame and shell design. It adheres to the world’s leading manufacturing standards, ensuring more stable operation. It can be equipped with automatic seeding and rear-loading systems, allowing for front-loading.

Electrical Characteristics:

1. lp55 protection level.

2. 304 stainless steel electrical cabinet.

3. Siemens operating system with touch screen human-machine interface product code and recipe code can be edited, mixing time and mixing management, production status and alarm information.

Stainless Steel Idustrial Horizontal Dough Mixer FAQ

Q: What is the difference between a horizontal mixer and a traditional mixer?

A: convenient for discharging. The dough quality is stable with a cooling jacket. The surface temperature is controllable. It has stable operation and long service life.

Q: Is the horizontal mixer easy to operate?

A: It have PLC control system, which is equipped with a display screen human-machine interface to achieve recipe management and more flexible and convenient daily operations.

Q: Is the horizontal mixer easy to clean?

A: The all-stainless steel body and open structure design are easy to clean and maintain.

Q: Does the horizontal mixer have internal leakage of pollutants?

A: The unique shaft seal design avoids the risk of internal leakage of contaminants.

Q: Which foods are suitable for horizontal mixers?

A: Hamburgers, toast, European-style panels, pizza, Mexican crusts, Chinese pastries, frozen dough, etc.

Q: What are the types of horizontal mixer?

A: 4 types. The production capacity is 150kg-450kg.

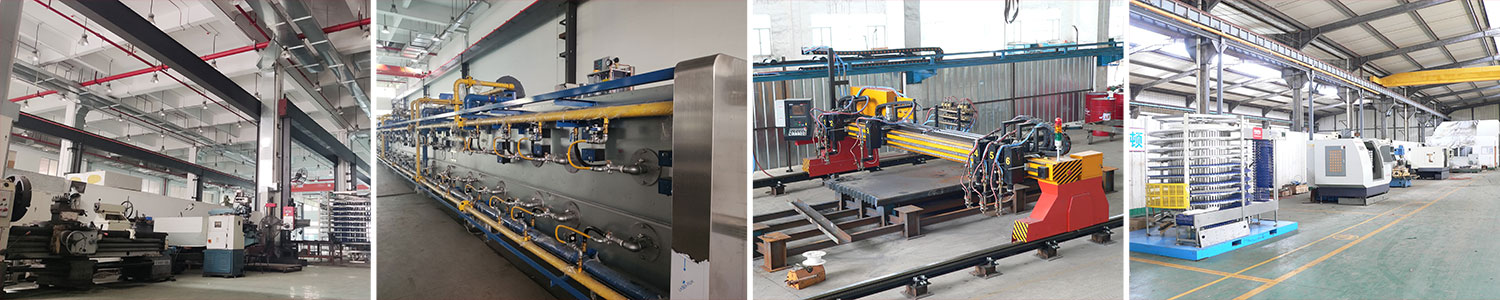

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

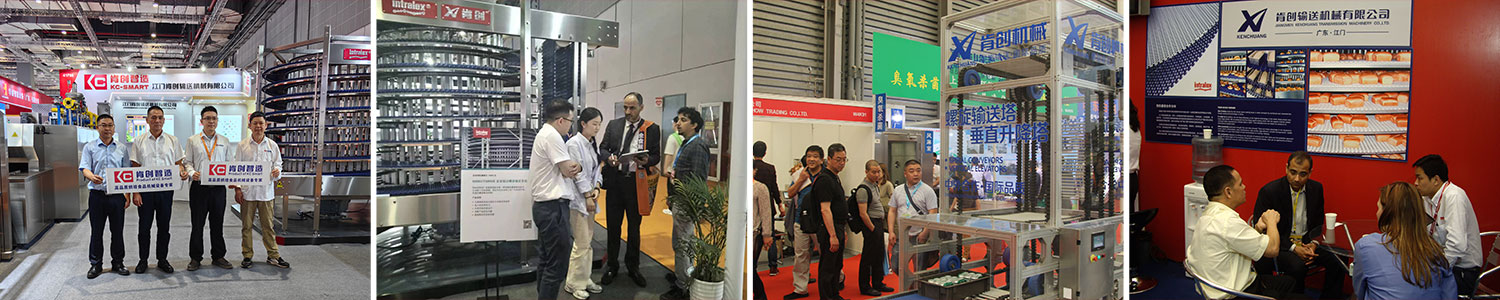

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

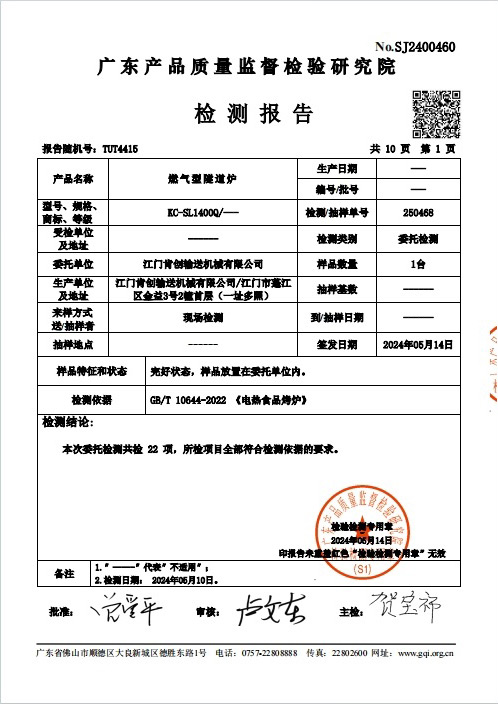

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

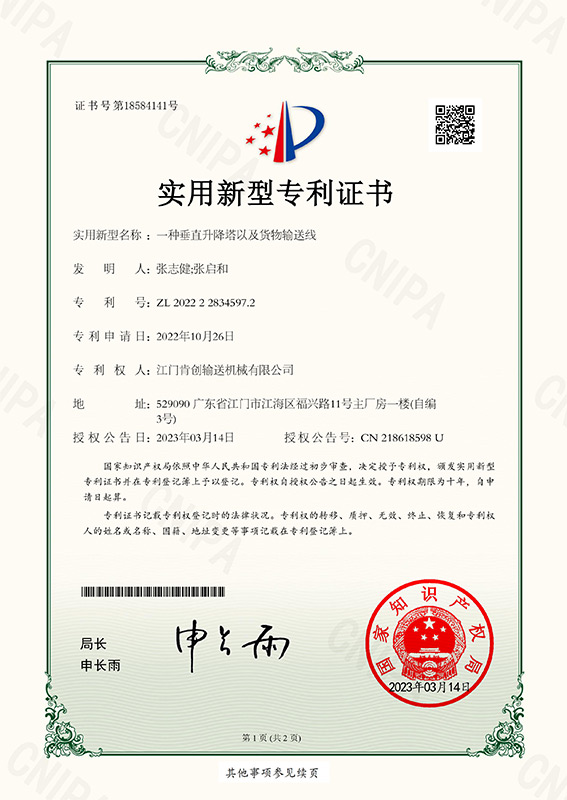

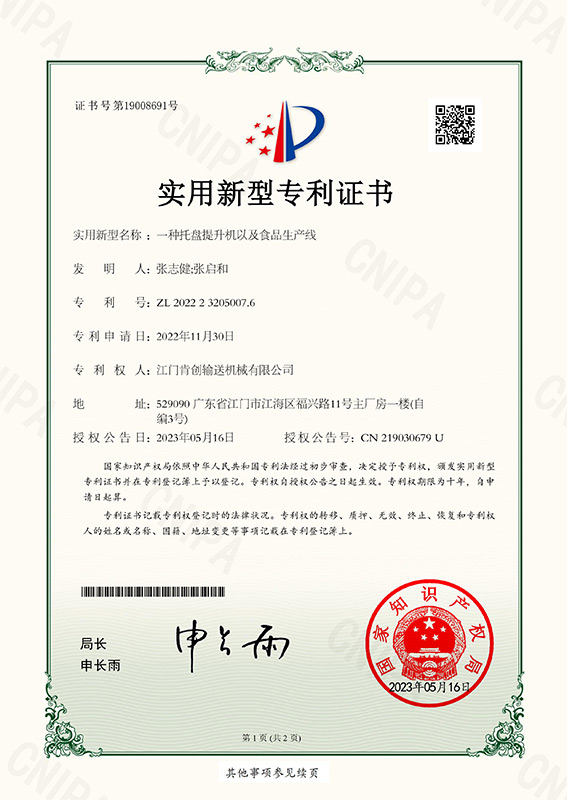

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.