Centralized Air Supply Gas-Fired Tunnel Oven

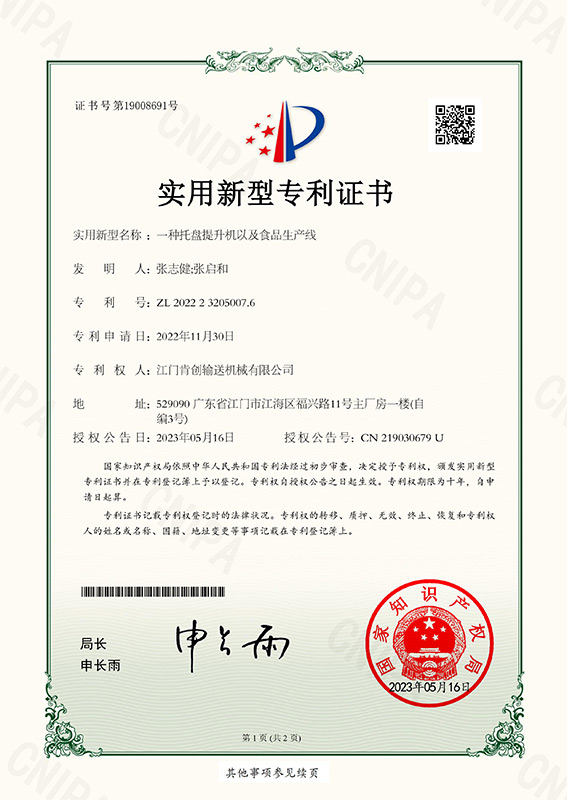

Gas-fired Tunnel Furnace

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

gas-fired tunnel ovens are baking devices used for food production such as moon-cakes, cakes, hamburgers, and toasts. The length of the Gas-fired tunnel oven can be customized according to the customer's production capacity. lt incorporates an advanced safety system with features such as intelligent ignition, automatic exhaust extraction of residual waste gas, flame failure detection, and pressure monitoring. Our factory stands out as a premier China gas-fired tunnel oven manufacturer, dedicated to providing high-quality, customized baking solutions for the global food industry.

Centralized Air Supply Gas-Fired Tunnel Oven:

In the baking area, each burner tube is supplied with oxygen by a branded large fan placed on top instead of domestic small oxygen supply fans. This avoids issues like ignition difficulties with small fans and ensures no disruption to production. The main gas pipeline of the tunnel oven is equipped with pressure reducing and stabilizing valves to ensure stable combustion flames. The rear area is equipped with multi-stage adjustable fire to ensure uniform product color.

Centralized Air Supply Gas-Fired Tunnel Oven Specifications

| Product Name | Centralized Air Supply Gas-fired Tunnel Furnace | ||

| Model | KCSL-1400Q | KCSL-2000Q | KCSL-2650Q |

| Ovenware Size | 400*600 | 400*600 | 400*600 |

| Size | 2470*2350 | 3070*2350 | 3720*2350 |

| Furnace Size | 770*1400 | 770*2000 | 770*2650 |

| Furnace Passing Height | 215 | 215 | 215 |

| Specification | Two Disks | Three Disks | Four Disks |

Centralized Air Supply Gas-Fired Tunnel Oven Advantage

As a trusted manufacturer and customized continuous tunnel furnace supplier, we focus on precision and efficiency in every product.

1. Adopting intelligent and PID control, as well as combustion proportion control,the zero-pressure proportional tunnel furnace achieves precise temperature control.

2. The furnace chamber utilizes aluminum plate to radiate heat energy, resulting in higher thermal efficiency and a reflectivity of 50%-70%. This saves energy, stabilizes the temperature inside the furnace, and reduces heat transfer to the exterior. It also avoids food contamination caused by paint peeling on the furnace chamber.

3. The conveyor chain and guide rail are made of manganese steel, which is wear-resistant at high temperatures and extends the service life by 30%-50%.

4. High-quality insulation cotton is used to increase thickness, reducing heat loss and external heat transfer, thereby saving energy consumption.

5. The rear section of the combustion fire tube uses adjustable multi-stage fire, allowing for adjustment of firepower size, which facilitates product quality adjustment.

6. The last two zones are equipped with hot air circulation, resulting in a more uniform color of the baked products.

7. The working principle of the zero-pressure proportional tunnel furnace is to fully mix air and natural go through a proportional motor and zero-pressure valve before combustion, ensuring complete gas combustion and thus saving energy consumption.

Centralized Air Supply Gas-Fired Tunnel Oven FAQ

Q: What are the key differences between the Centralized Air Supply Gas-Fired Tunnel Oven and the Zero-Pressure Proportional Tunnel Oven?

A: The main difference lies in their temperature control systems. While both ovens offer precise temperature control and stable flame combustion with a hot air circulation system for even product coloration, the Zero-Pressure Proportional Tunnel Oven features an additional proportional motor and an air-fuel ratio valve, enabling even more precise temperature adjustments.

Q: How does the hot air circulation system ensure even baking in your gas-fired tunnel ovens?

A: The hot air circulation system within our tunnel ovens ensures that heated air is evenly distributed throughout the oven chamber. This not only promotes uniform baking but also helps achieve consistent product coloration and texture. The continuous circulation of hot air minimizes temperature gradients, resulting in superior baking quality.

Q: Are your tunnel ovens energy-efficient?

A: Yes, our gas-fired tunnel ovens are designed with energy efficiency in mind. The stable flame combustion and precise temperature control minimize energy waste. Additionally, the efficient hot air circulation system contributes to faster heat transfer, further reducing energy consumption.

Q: Can your gas-fired tunnel ovens handle large-scale production requirements?

A: Absolutely. Our gas-fired tunnel ovens are built to withstand heavy-duty use in commercial and industrial settings. Their continuous conveyor belt design allows for seamless product flow, making them ideal for high-volume production lines.

Q: What safety features do your gas-fired tunnel ovens incorporate?

A: Our gas-fired tunnel ovens come equipped with multiple safety features, including but not limited to overheat protection, flame failure detection, and emergency stop buttons. These features ensure the safe operation of the oven and protect against potential hazards, such as fire or excessive heat build-up.

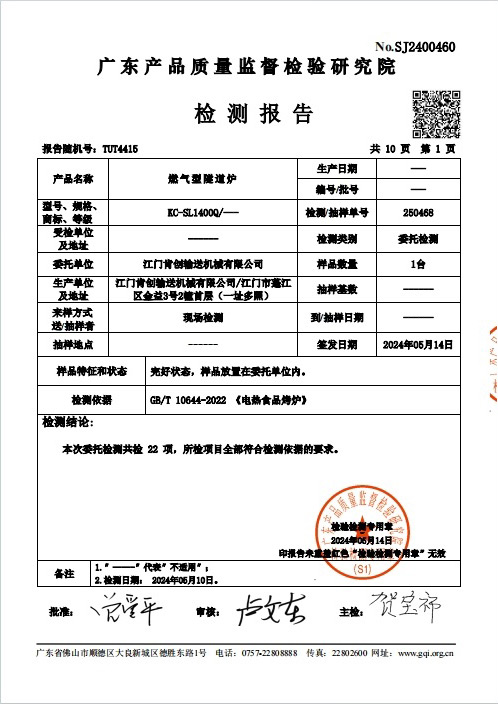

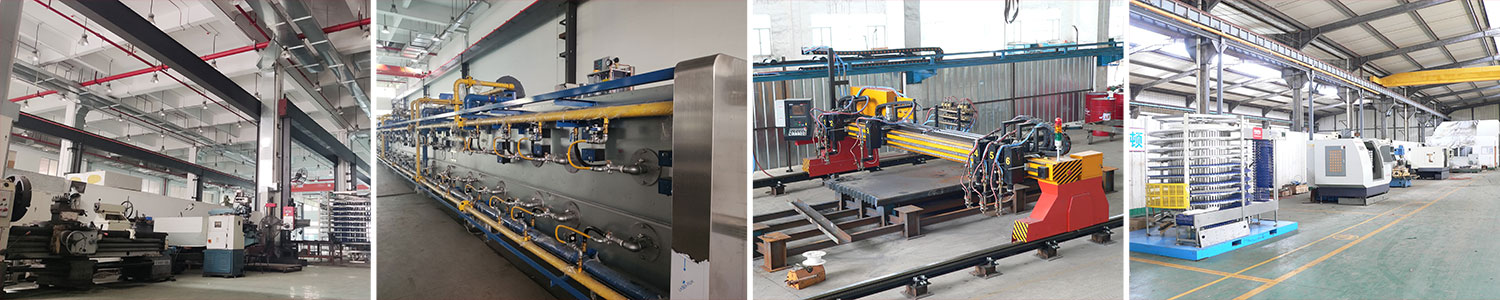

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

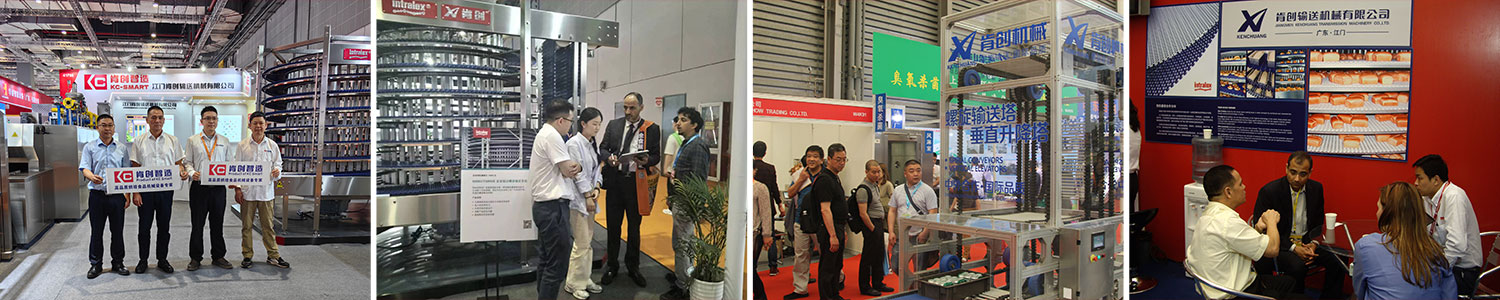

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

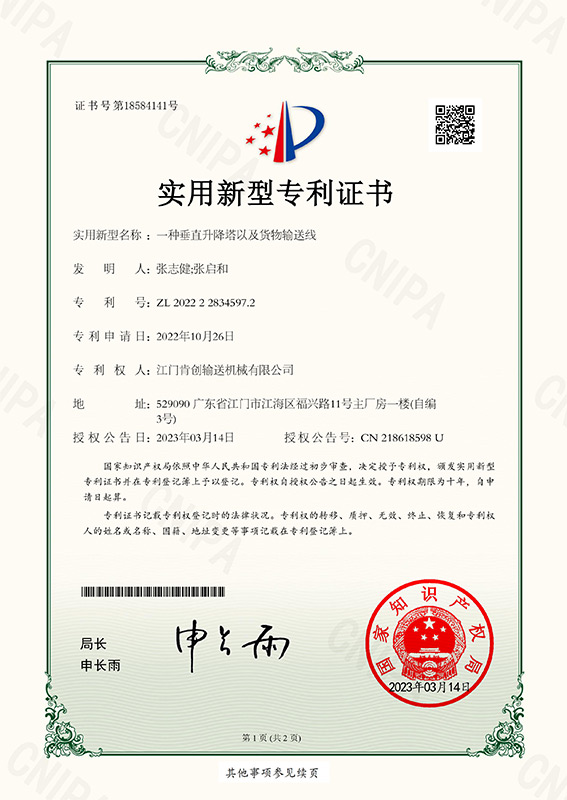

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.