Intelligent Direct Gas Fired Oven

Gas-fired Tunnel Furnace

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

Direct Gas Fire Oven is an efficient baking equipment designed specifically for baking food. It generates heat by directly burning gas and uses a hot air circulation system to uniformly heat food, achieving the desired baking effect. This tunnel furnace is widely used in the production of various baked goods and can meet the baking needs of food enterprises of different scales and types.

Intelligent Direct Gas Fired Oven Parameters

| Product Name | Centralized Air Supply Gas-fired Tunnel Furnace | ||

| Model | KCSL-1400Q | KCSL-2000Q | KCSL-2650Q |

| Ovenware Size | 400*600 | 400*600 | 400*600 |

| Size | 2470*2350 | 3070*2350 | 3720*2350 |

| Furnace Size | 770*1400 | 770*2000 | 770*2650 |

| Furnace Passing Height | 215 | 215 | 215 |

| Specification | Two Disks | Three Disks | Four Disks |

| OEM/ODM | Accept | ||

| Compay Nature | China Manufacturers Suppliers Factory | ||

Intelligent Direct Gas Fired Oven Features

1. Precise temperature control system

This Direct Gas Fire Oven adopts intelligent PID control and combustion proportional control technology, and the zero pressure proportional tunnel furnace can achieve precise temperature control. Intelligent PID control can automatically adjust the heating power according to temperature changes, ensuring that the temperature inside the furnace remains within the set range. The combustion ratio control dynamically adjusts the gas supply based on the combustion situation, making temperature control more precise and meeting the strict temperature requirements of different baked goods.

2. Efficient thermal radiation furnace chamber

The furnace chamber uses aluminum plates for thermal energy radiation, with high thermal efficiency and a reflectivity of up to 50% -70%. Aluminum plates have good thermal conductivity and reflectivity, which can quickly and evenly distribute heat throughout the entire furnace cavity, reducing energy waste. At the same time, the surface of the aluminum plate is smooth and not prone to dust accumulation, avoiding the problems of heat conduction efficiency and food hygiene affected by dust.

3. High temperature resistant conveyor chain and guide rail

The conveyor chain and guide rail are made of manganese steel material, which has excellent high temperature resistance and wear resistance, and the service life can be extended by 30% -50%. Manganese steel can maintain high strength and stability in high temperature environments, ensuring smooth and steady transportation of food and reducing production interruptions and maintenance costs caused by equipment wear.

4. High quality insulation and heat preservation

The Direct Gas Fire Oven uses high-quality insulation cotton and increases its thickness to effectively reduce heat loss and external heat transfer, saving energy consumption. Thermal insulation cotton can effectively block heat radiation outward, maintain stable temperature inside the furnace, reduce energy waste, and lower workshop temperature, improving the working environment.

5. Adjustable multi-stage firepower combustion tube

The rear section of the combustion tube adopts an adjustable multi-stage firepower design, which can flexibly adjust the firepower size according to production needs, facilitating product quality adjustment. By adjusting the firepower, the baking speed and temperature can be controlled to meet the requirements of different foods for baking time and temperature, and improve the stability of product quality.

1. Mooncake production

In mooncake production, Direct Gas Fired Oven can provide a stable high-temperature environment, ensuring even heating of mooncakes, ensuring golden and crispy crust, and fully matured filling. Its precise temperature control system can meet the baking temperature requirements of different flavors of mooncakes. Whether it is traditional five nut mooncakes or Cantonese bean paste mooncakes, it can ensure high-quality baking effects and improve the yield and quality of mooncakes.

2. Cake making

For cake making, the Direct Gas Fire Oven's hot air circulation system ensures even heating, consistent surface color, and delicate internal structure during the baking process. The efficient heat transfer in the aluminum plate heat radiation furnace cavity can shorten the baking time and improve production efficiency. Meanwhile, the intelligent control of the device can reduce human operation errors and ensure stable quality of each batch of cake.

3. Burger processing

During the hamburger processing, Gas fired Tunnel Fumace can uniformly heat both the upper and lower sides of the burger embryo, making its surface golden and crispy, and its interior soft and porous. The adjustable multi-stage firepower combustion tube of the equipment can flexibly adjust the firepower size according to different sizes and formulas of hamburgers, ensuring consistent baking effect. Moreover, the continuous production mode of tunnel furnaces can significantly increase the yield of hamburger embryos and meet the demand for large-scale production.

4. Toast baking

Toast baking requires strict control over temperature and time. The precise temperature control system and high-quality insulation design of this equipment ensure that toast is slowly baked at the appropriate temperature, fully fermented, with uniform internal structure and a soft texture. The hot air circulation system ensures even heating on all sides of the toast, avoiding local dryness or undercooking, and improving product quality.

5. Other baked goods

In addition to the common baked goods mentioned above, it can also be used for the production of various baked goods such as biscuits, bread, and pastries. Its flexible customization capability and strong adaptability enable it to meet the diverse needs of different baking enterprises, improve production efficiency and product quality.

Intelligent Direct Gas Fired Oven Maintenance

1. Daily cleaning

After each use, the residue and oil stains in the furnace chamber should be promptly cleaned to prevent excessive accumulation that may affect equipment performance and food hygiene. You can use a soft cloth dipped in an appropriate amount of cleaning agent to gently wipe the interior of the furnace chamber, avoiding the use of hard brushes or sharp tools to scrape and damage the surface of the furnace chamber. At the same time, check and clean the debris on the conveyor chain and guide rail to ensure their smooth operation.

2. Regularly inspect the combustion system

Regularly inspect components such as burners, gas pipelines, and valves to ensure normal gas supply and no leakage hazards. Observing the color and shape of the burning flame, a normal burning flame should be blue and stable. If abnormal flames or signs of leakage are found, the machine should be immediately shut down for maintenance, and professional personnel should be contacted for handling to ensure the safe operation of the equipment.

3. Check the transmission system

Regularly check the tension of the conveyor chain and the wear of the guide rails to ensure smooth operation of the transmission system. If the conveyor chain is found to be loose, adjust the tension in a timely manner; If the guide rail is worn, the corresponding components should be replaced to prevent poor food delivery or equipment damage caused by transmission failure.

4. Maintain the thermal insulation layer

Regularly check the integrity of insulation layers such as insulation cotton and insulation boards. If there is any damage or aging, they should be repaired or replaced in a timely manner. A complete insulation layer can effectively reduce heat loss, save energy consumption, reduce workshop heat accumulation, and improve the working environment.

5. Equipment lubrication

Regularly lubricate the rotating components such as bearings and gears of the equipment, and select appropriate lubricants and lubrication cycles according to the requirements of the equipment manual. Good lubrication can reduce component wear, lower equipment operating noise, and extend equipment lifespan.

6. Electrical system inspection

Regularly inspect the electrical control system of the Direct Gas Fire Oven, including wires, cables, terminal blocks, etc., to ensure secure connections, no looseness, short circuits, or aging. At the same time, check whether the buttons, switches, sensors and other components on the control panel are sensitive and reliable. If there are any abnormalities, they should be repaired or replaced in a timely manner to ensure the normal operation and safe operation of the equipment.

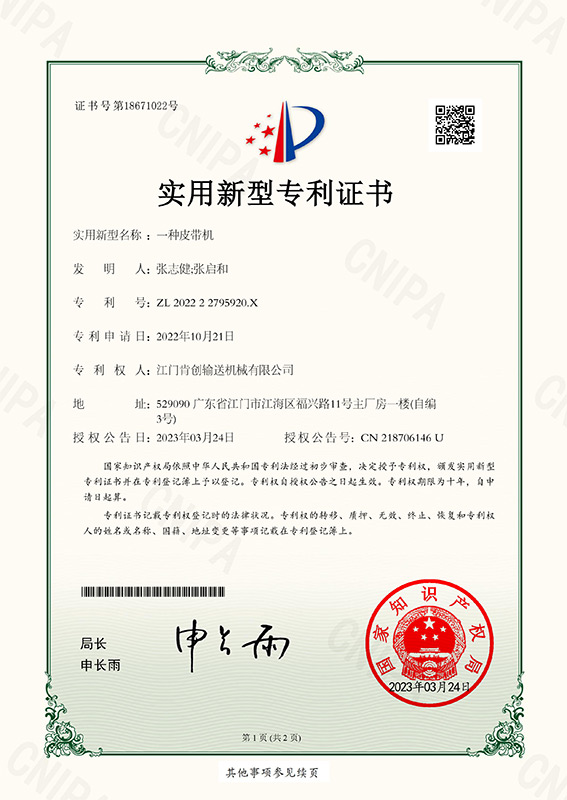

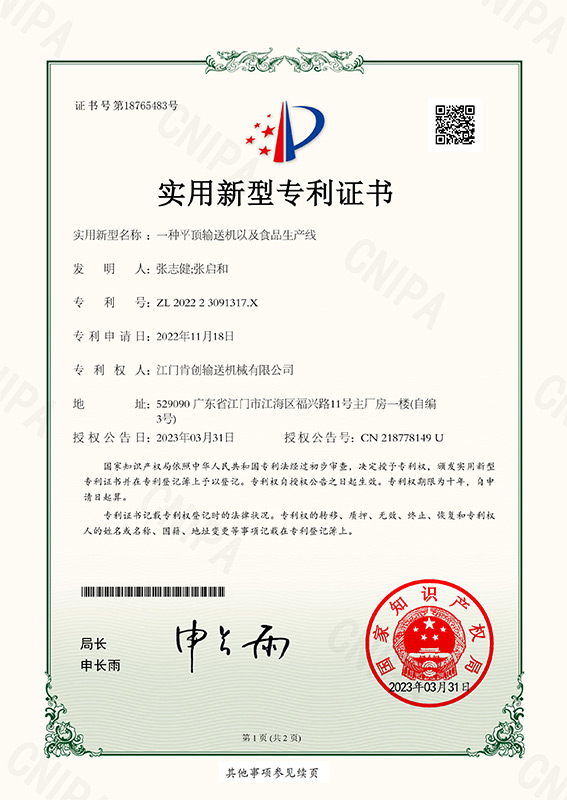

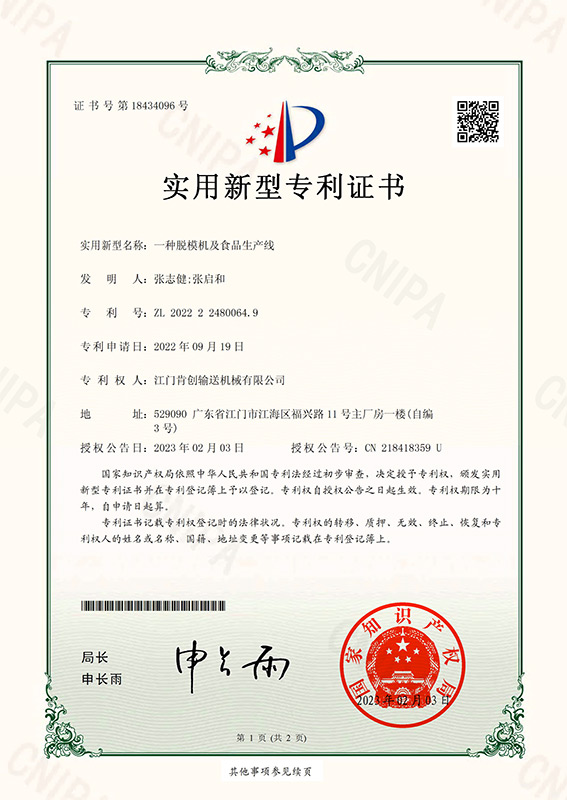

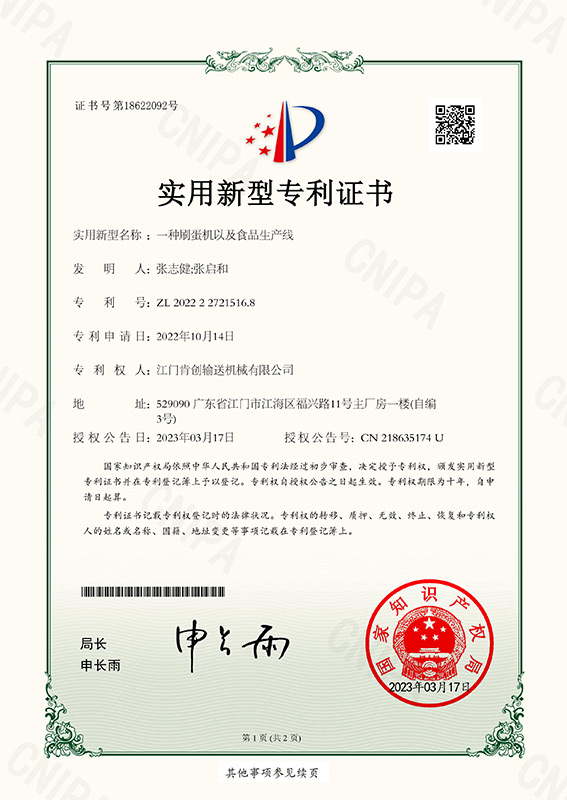

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.