Bagged Flour Feeding Machine

Flour Dosing Station

-

+86-13427473518 WhatsApp

-

kc001@jm-kc.com Email

This Bagged Flour Feeding Machine performs critical functions, including bagged flour feeding, dust removal, and screening, providing a comprehensive solution for flour handling needs. Engineered to enhance productivity, it features a robust screening rate of 50 kg per minute, ensuring rapid and efficient processing for high-demand environments. The flour feeding machine integrates dust control technology to maintain a clean workspace, crucial for industries where hygiene and cleanliness are top priorities. The unit’s efficient dust removal system reduces airborne particles, protecting both product quality and worker safety. The screening function also ensures uniform flour quality by filtering out impurities, achieving a consistent, high-quality output. As a China flour feeding machine supplier, KC-SMART’s flour dosing station is an ideal choice for industrial kitchens, bakeries, and food processing facilities.

Bagged Flour Feeding Machine Specifications

| Product Name | Flour Dosing Station |

| Screening Rate | 50kg/min |

Bagged Flour Feeding Machine Advantage

Our customized flour feeding machine exemplifies our commitment to innovation and adaptability.

1. Fast and Efficient Flour Feeding: This machinery feeds the bagged flour automatically thereby reducing the feeding time and labor in the production area in case of heavy work load.

2. Remarkable Screening Rate: The Flour Feeding Machine, with a screening rate of 50 kg per minute, guarantees timely service for all processing which is critical for bulk operations.

3. Efficient Dust Control: Advanced dust suppression technology reduces dust emissions into the environment, keeping the work area clean and safe. This is important in industries that have strict hygienic regulations.

4. Quality Improvements: The system’s screening function is performed through sieving, which allows achieving a reasonable flour quality control. As a result, product variety is maintained, and the quality of final output is improved.

5. Logistical Simplicity and Ease of Use: Simple and easy to use, the machine can be effectively incorporated into a new or existing production line without complex installation requirements.

6. Strength and Performance: Enhanced operational efficiency, good performance and long life of the machine makes it an economical investment for food processing facilities because it is made from heavy-duty materials.

7. Space-Efficient Approach: The Flour Feeding Machine is small and space saving which is advantageous for zone restrain installations to effectively make the use of the area provided.

Bagged Flour Feeding Machine FAQ

Q: What is the screening capacity of this flour feeding machine?

A: Our flour feeding machine boasts a powerful screening capacity, capable of processing 50 kilograms of flour per minute.

Q: What are the advantages of using this flour feeding machine?

A: The machine efficiently screens flour, ensuring its fineness and uniformity, thereby enhancing the quality and efficiency of food production.

Q: Can this machine meet my needs if I have a large-scale production?

A: Absolutely, our flour feeding machine is designed to handle large volumes of flour, making it ideal for large-scale food production environments.

Q: Is this flour feeding machine easy to maintain and clean?

A: Yes, our flour feeding machine features a simple design that is easy to dismantle and clean, ensuring hygiene and safety during production.

Q: Can I customize the size or configuration of this machine if I have special requirements?

A: Of course, we offer customization services and can adjust the size and configuration of the machine according to your specific needs.

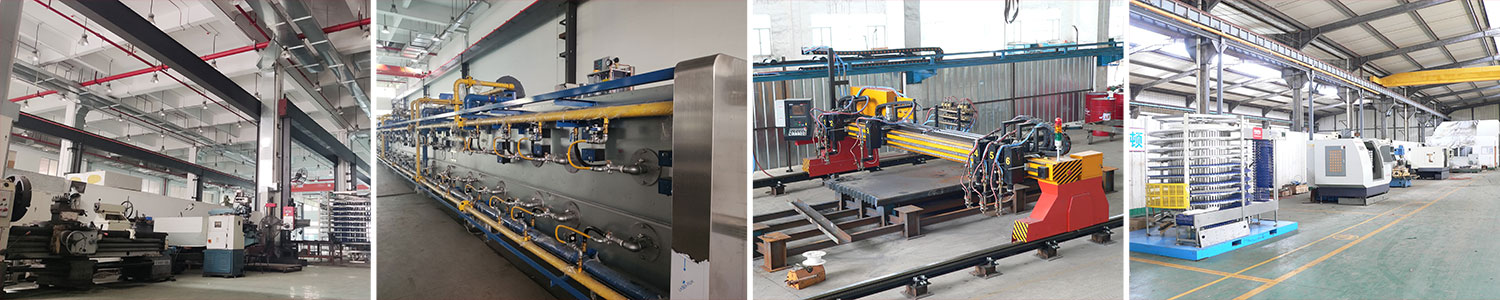

Production Environment

With advanced equipment and skilled personnel, we provide customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment.

Engineering Cases

We deeply understand that every customer has diverse needs. Therefore, we provide professional customized baking solution services, tailoring baking engineering machines according to customers' actual requirements. From the functional configuration to the design of the machine, we fully consider customers' personalized needs to ensure that every machine becomes a proud product for the customer.

Application Scenarios

KC-SMART provides cutting-edge solutions tailored to the baking industry. Our intelligent mechanical equipment is widely used in the production of diverse baked goods, including bread, mooncakes, cookies, and cakes.

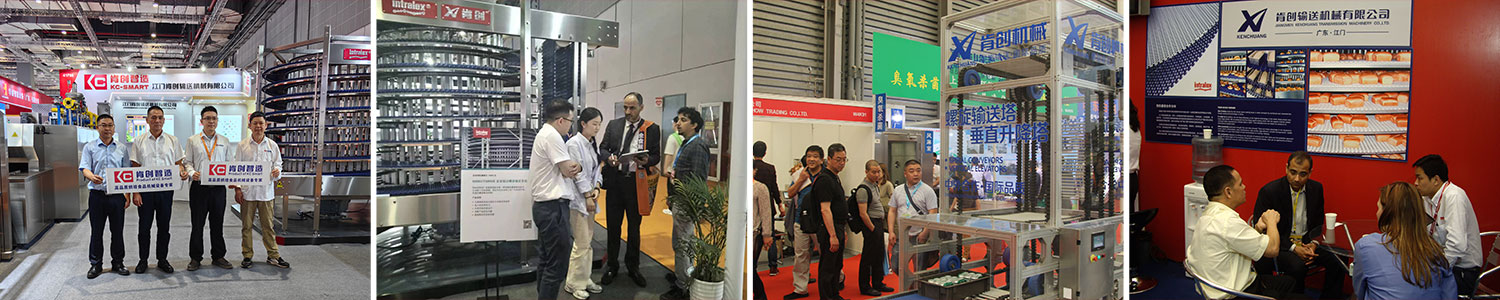

Exhibitions

At KC-SMART, we actively participate in industry-leading trade shows to showcase our advanced intelligent mechanical equipment for the global baking industry. These exhibitions provide an excellent platform to connect with clients, discuss their specific needs, and demonstrate our solutions for powder transportation, mixing, fermentation, baking, cooling, and material handling.

KC-SMART founded in 2000, is a high-tech enterprise dedicated to providing global baking food customers with one-stop solutions, including customized design, manufacturing, installation, debugging, and after-sales maintenance of intelligent mechanical equipment. Guided by the values of "willingness to work hard and innovate, and win-win future" and the business philosophy of "honesty, quality, responsibility, and respect for talents," the company strives to deliver the best possible service.

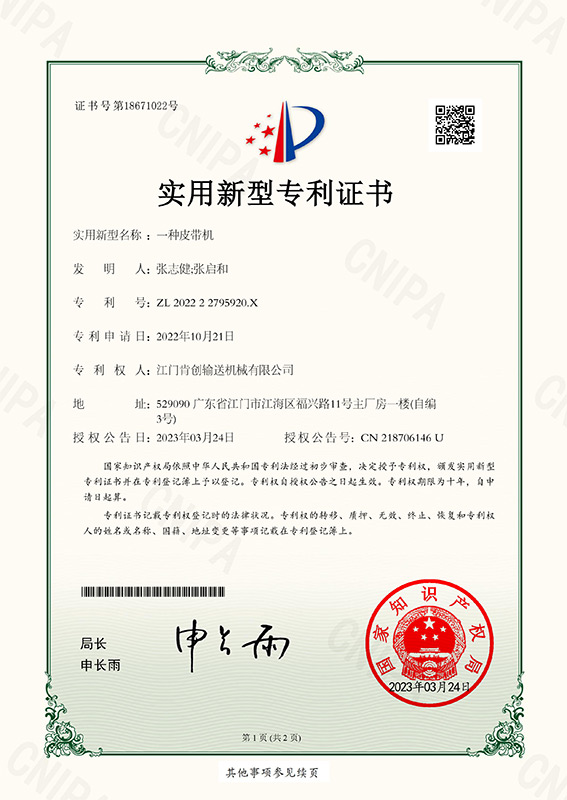

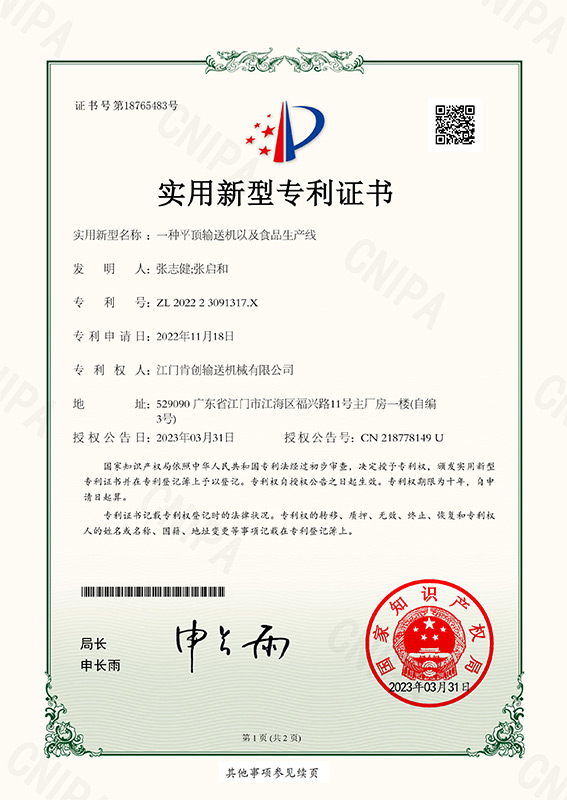

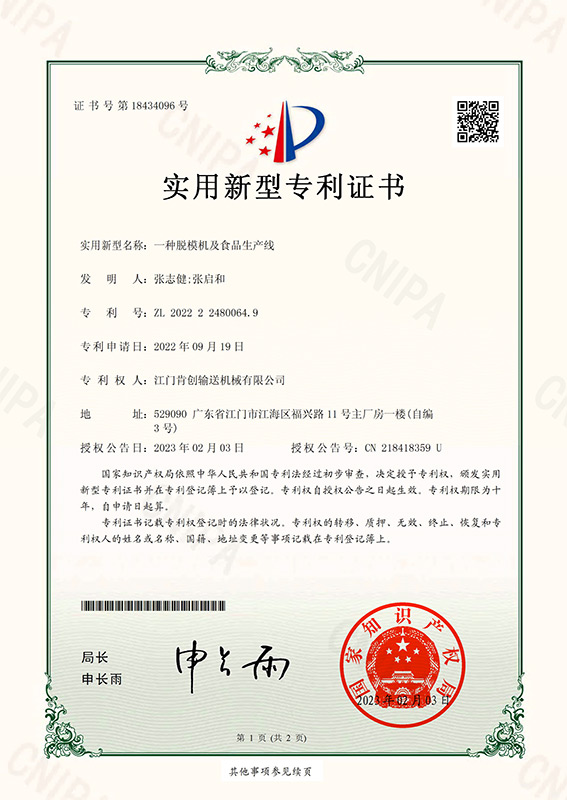

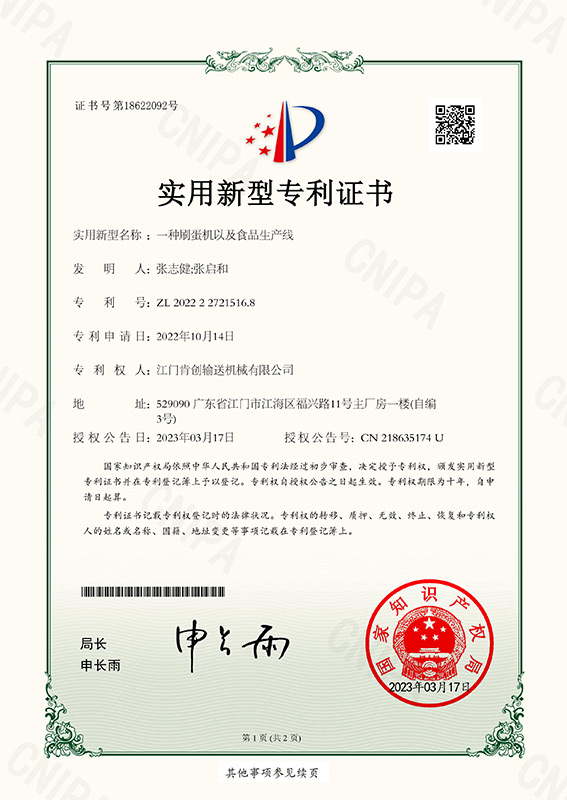

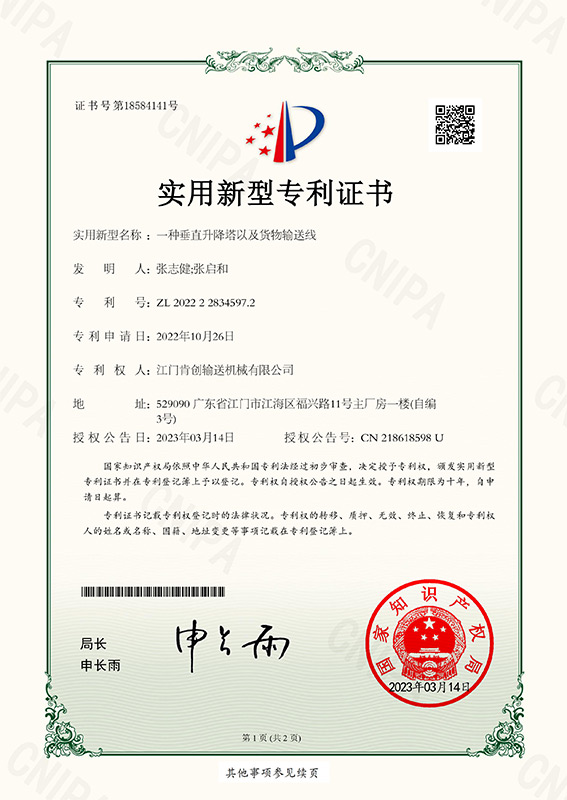

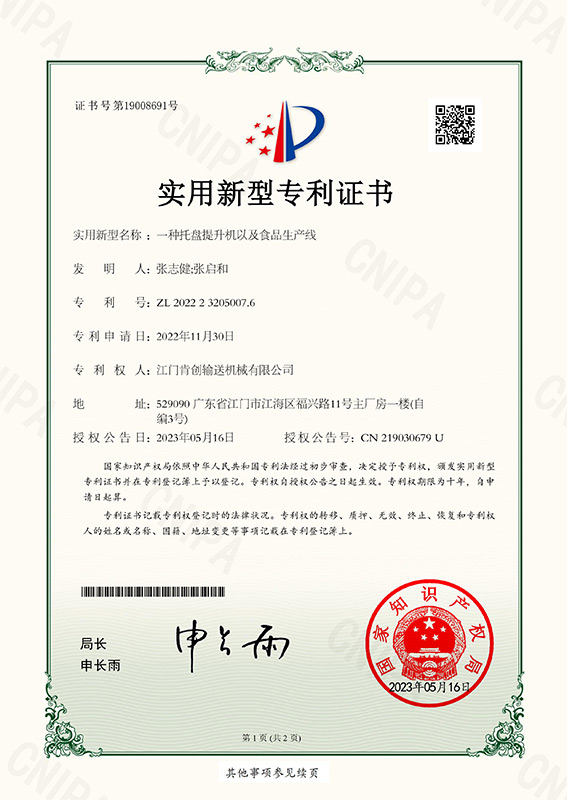

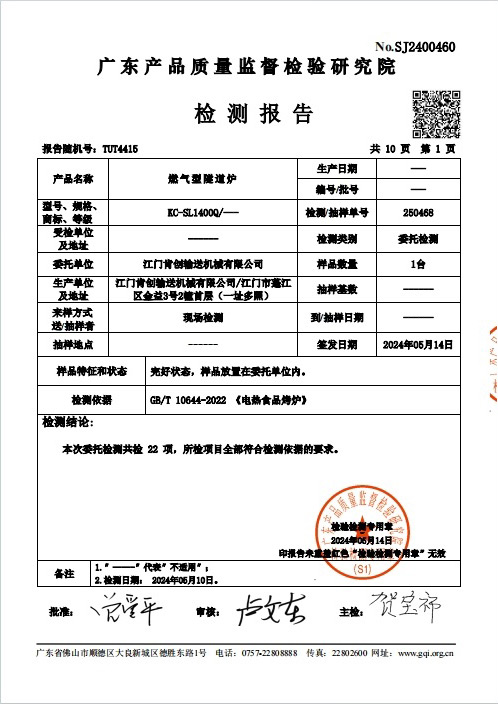

Located at No. 3 Jinyi Road, Pengjiang District, jiangmen City, Guangdong Province, the company covers an area of over 10,000 square meters. Its product line includes intelligent mechanical equipment for powder transportation, mixing, fermentation, baking, cooling, demolding, and material handling, among others. The company also holds multiple practical invention patents.

Looking ahead, Jiangmen Kenchuang Conveying Machinery Co, Ltd. will continue to uphold the spirit of innovation, constantly improve product quality and service levels, and provide even more intelligent and efficient mechanical equipment solutions for global baking food customers. Together, we aim to create a brighter future for all.